There are actually three different GM big block water pump nose depths, not just two as common knowledge would have us believe. The factory pump for a tall deck industrial engine (366T/427T or 366 cubic inch tall deck/427 cubic inch tall deck) is approximately 6-3/8" from block to pulley mount surface. Long nose is approximately 7-5/8" from block to pulley mount surface. Short nose is 5-7/8" from block to pulley mount surface. The tall deck industrial pump has a unique bypass housing on top of the pump using a 1-3/4" hose from the intake manifold front. It also has a 2-3/4" intake hose from radiator. The upper radiator hose (output) of the tall deck pump to the radiator is 2". There's plenty of common knowledge out there about the standard long and short nose pumps, so we're mainly concerned with documenting the lesser known tall deck industrial engine pump.

Any pump can be used with the tall deck engine, as long as the bypass from the intake manifold is adapted to fit. The standard long and short nose pumps will usually not work with stock tall deck crankshaft pulleys or fans out of the box, as the tall deck pump has a 2.5" pulley bolt circle and a larger hub. The pump bodies themselves are not too much larger other than the enlarged bypass adapter on top of the industrial pump. The factory tall deck pump is made to flow a higher volume of coolant than the factory short or long nose pumps, thus the much larger intake size.

Below are physical comparisons of the three pumps. In the lefthand picture we've placed a bar across the noses for height comparison. On the left is a short nose pump, the middle one is a stock industrial tall deck pump, and the long nose pump is on the right. Note: some industrial engines have a pump that is offset up higher to place the fan in the middle of a taller radiator, such as those used on heavy trucks. The pump shown below is for a standard height radiator.

An example of a tall style industrial pump:

As usual with all water pumps, impellers turn in a direction such that the fluid is pushed, not scooped, through the pump. Straight vane impellers are the exception (versus perpendicular to the shaft) and shrouded impellers. Straight-vane impellers work in both directions. Shrouded impellers turn so the fluid is 'scooped'. The examples below show the impeller side of the pump; the rotation on the hub side is obviously opposite.

Since the factory industrial tall deck engines are sort of ignored by most chevy builders, there's not much out there in the way of solid information about them. The cylinder heads have a lot of disinformation in general.

The cylinder heads are not all actually specific to the tall deck engines. They mostly utilize the same factory castings as other big blocks, obviously with some variation over time. The valves ARE different though. The tall deck engines use sodium filled valve stems for better cooling. There's a lot of good information about how that works out there, so we won't go into it here. The valve springs and rocker arms are not anything special, as these engines were not made to turn high revolutions per minute, instead specializing in low end grunt power.

As can be seen below, this set of factory heads off of a 1972 366T engine is a standard oval port casting.

Visual indication of standard head use: as can be seen below, the head gaskets on this factory 366 cubic inch engine used standard size gaskets. This means the distance between cylinders on the gasket surface is not different between tall deck engines and standard engines, regardless of displacement. Tall deck engines are no less likely to incur headgasket failure due to this spacing than a standard engine. In the photo can be seen how much smaller the 366 cylinder bore is than the gasket which sits on it (and yes, this is the first disassembly of a factory engine). Not visible in the photo is the slight notch beveled out of the upper cylinder wall side for intake valve clearance on this small 366 cu. in. bore.

Another difference in cylinder heads has to to with the generation change of the blocks in 1991. The water jacket passages in the head can be different, as illustrated by the picture below.

Below is some reference data for cylinder head casting numbers with valve sizes, years used, etc.

Casting numbers used on factory 366ci tall deck engines (some used on multiple engines):

*ending 328: 1980 through 1991. Used on RPO: L86 (1980-1991).

330864: 1968 through 1991 oval port, open chamber, 2.06 in. intake and 1.72 in. exhaust valves. Used on RPO: L86 (1980-1991).

330865: 1968 through 1984 oval port, open chamber, 2.06 in. intake and 1.72 in. exhaust valves.

330866: 1968 through 1978 oval port, open chamber, 2.06 in. intake and 1.72 in. exhaust valves.

343771: 1968 through 1991 oval port, open chamber, 2.06 in. intake and 1.72 in. exhaust valves. Used on RPO: L86 (1980-1991).

343772: 1968 through 1986 oval port, open chamber, 2.06 in. intake and 1.72 in. exhaust valves.

473328: 1968 through 1969 oval port, open chamber, 2.06 in. intake and 1.72 in. exhaust valves.

3856213: 1966 through 1982 oval port, closed chamber, 2.19 in. intake and 1.88 in. exhaust valves.

3904393: 1968 through 1991 oval port, open chamber, 2.19 in. intake and 1.88 in. exhaust valves. Used on RPO: L86 (1980-1991).

3917219: 1968 through 1991 oval port, open chamber, 2.06 in. intake and 1.72 in. exhaust valves. Used on RPO: L86 (1980-1991).

3933148: 1969 through 1984 oval port, open chamber, 2.06 in. intake and 1.72 in. exhaust valves.

3975950: 1968 through 1970 oval port, open chamber, 2.06 in. intake and 1.72 in. exhaust valves.

3986133: 1968 through 1985 oval port, open chamber, 2.06 in. intake and 1.72 in. exhaust valves.

3986135: 1969 through 1973 oval port, open chamber, 2.06 in. intake and 1.72 in. exhaust valves.

3986136: 1968 through 1984 oval port, open chamber, 2.06 in. intake and 1.72 in. exhaust valves.

10101140: 1991 and later oval port, closed chamber, 2.06 in. intake and 1.72 in. exhaust valves. Used on RPO: LS0 (1990-1998).

10487052: 1977 through 1991 oval port, open chamber, 2.06 in. intake and 1.72 in. exhaust valves. Used on RPO: L86 (1980-1991).

12562932: 1991 through 1995 oval port, open chamber, 2.06 in. intake and 1.72 in. exhaust valves. Used on Gen V truck crate.

12562933: 1991 through 1995 oval port, open chamber, 2.06 in. intake and 1.72 in. exhaust valves. used on RPO: LS0 (1990-1998).

14081052: 1985 through 1987 oval port, open chamber, 2.06 in. intake and 1.72 in. exhaust valves. May be stamped “Hi Perf”.

14092359: 1986 through 1990 oval port, open chamber, 2.06 in. intake and 1.72 in. exhaust valves. May be stamped “Hi Perf”.

Casting numbers used on factory 427ci tall deck engines (some used on multiple engines):

330864: 1968 through 1984 oval port, open chamber, 2.06 in. intake and 1.72 in. exhaust valves.

330865: 1968 through 1984 oval port, open chamber, 2.06 in. intake and 1.72 in. exhaust valves.

330866: 1968 through 1978 oval port, open chamber, 2.06 in. intake and 1.72 in. exhaust valves.

330867: 1968 through 1973 oval port, open chamber, 2.06 in. intake and 1.72 in. exhaust valves.

336765: 1968 through 1978 oval port, open chamber, 2.06 in. intake and 1.72 in. exhaust valves.

336768: 1973 through 1976 oval port, open chamber, 2.06 in. intake and 1.72 in. exhaust valves.

343771: 1968 through 1986 oval port, open chamber, 2.06 in. intake and 1.72 in. exhaust valves.

343772: 1968 through 1986 oval port, open chamber, 2.06 in. intake and 1.72 in. exhaust valves.

366765: 1974 through 1978 oval port, open chamber, 2.06 in. intake and 1.72 in. exhaust valves.

3856213: 1966 through 1982 oval port, closed chamber, 2.19 in. intake and 1.88 in. exhaust valves.

3876875: 1977 through 1985 oval port, open chamber, 2.19 in. intake and 1.88 in. exhaust valves.

3908952: 1967 oval port, open chamber, 2.19 in. intake and 1.88 in. exhaust valves. Truck and marine.

3917219: 1968 through 1985 oval port, open chamber, 2.06 in. intake and 1.72 in. exhaust valves.

3933148: 1969 through 1984 oval port, open chamber, 2.06 in. intake and 1.72 in. exhaust valves.

3933149: 1968 through 1976 oval port, open chamber, 2.06 in. intake and 1.72 in. exhaust valves.

3935401: 1968 through 1976 oval port, open chamber, 2.06 in. intake and 1.72 in. exhaust valves.

3975950: 1968 through 1970 oval port, open chamber, 2.06 in. intake and 1.72 in. exhaust valves.

3986133: 1968 through 1985 oval port, open chamber, 2.06 in. intake and 1.72 in. exhaust valves.

3986135: 1969 through 1973 oval port, open chamber, 2.06 in. intake and 1.72 in. exhaust valves.

3986136: 1968 through 1984 oval port, open chamber, 2.06 in. intake and 1.72 in. exhaust valves.

10052902: Oval port, open chamber, 2.06 in. intake and 1.72 in. exhaust valves. Mark IV crate and truck.

10101140: 1991 and later oval port, closed chamber, 2.06 in. intake and 1.72 in. exhaust valves.

12562932: 1991 through 1995 oval port, open chamber, 2.06 in. intake and 1.72 in. exhaust valves. Used on Gen V truck crate.

12562933: 1991 through 1995 oval port, open chamber, 2.06 in. intake and 1.72 in. exhaust valves. Used on Gen V.

14081052: 1985 through 1987 oval port, open chamber, 2.06 in. intake and 1.72 in. exhaust valves. May be stamped “Hi Perf”.

14092359: 1986 through 1990 oval port, open chamber, 2.06 in. intake and 1.72 in. exhaust valves. May be stamped “Hi Perf”.

Most (if not all) of the tall deck engines were installed with one 'U' shaped engine mount bolted to the front of the engine, with the rear support being on either side of the bellhousing. The blocks were still drilled and tapped for side 'clamshell' style mounts however. So engine mounting is an easy conversion to standard big block mounts. The starter motor was usually mounted in the bellhousing, so not all engine blocks have drilled and tapped starter motor holes. Early blocks are drilled and tapped, not all later blocks are. At some point GM figured out that they weren't installing automatic transmissions on these and that they could save some money by not making or preparing the holes.

Accessory mounting to the front of the engine will be slightly different than standard big blocks due to the fact that the cylinder heads are slightly farther apart. The easiest way to overcome this if not using the complete factory bracket setup is to obtain bracket sets that mount only to the block or heads respectively for each accessory. This eliminates the problem of bolt hole spacing being slightly different between the block and head.

If using a stock cast crankshaft pulley with four or more grooves, note that the grooves begin immediately after the damper. This places the innermost belt very close to the water pump housing on a regular big block pump, and the short nose version must be used in this case. It will be tight, but it will clear most castings. The pump housing may have to be filed slightly or deburred if the belt rubs on installation. Note on the pump comparison pictures above in the water pumps topic, the industrial pump in the middle actually has more housing clearance although it is bigger in other ways.

Here is a short-nose standard big block pump on a tall deck engine with the two innermost belts driving the alternator mounted on the passenger side.

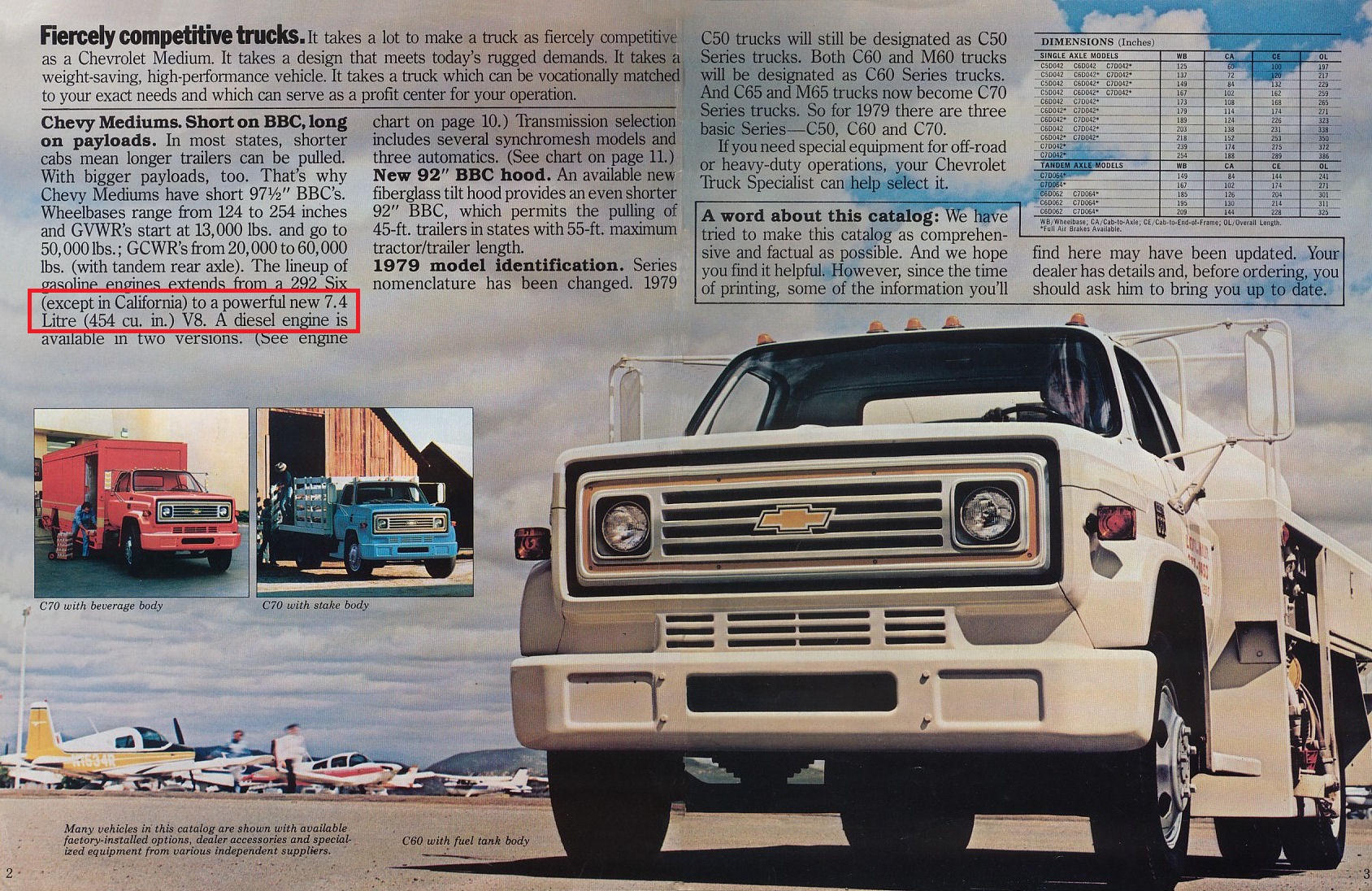

Shown here is a typical industrial/commercial engine setup used in larger trucks. Evident is how different the commercial accessory setup is from a typical big block used in small trucks and cars. This is from a C65 Chevrolet circa 1969, adapted to a non-governed carburetor and HEI ignition, but still typical of the era:

Note the v-belt idler pulleys, used for adjusting belt tension. These were only used on the commercial engines and are hard to locate individually.

Note: the belt idler for the power steering pump and air compressor in 1974 uses bearing NSK 885165. This may apply to other years as well.

All intake manifolds up until 1969 are 2 bbl versions, with the 4 bbl becoming available starting in 1969. The 2 bbl versions are getting difficult to find as much fewer of these were made, and of course are less desireable from a power standpoint.

The tall deck intake manifolds are unique to the application. They are a two-plane, cast-iron design, with each side of the carburetor feeding four cylinders. This design encourages low end power, which is what these engines are designed for. The 4bbl carburetor mounting pad is a square bore, designed to accept a specific Holley carburetor with a vacuum governor to limit RPM.

The distributor mounting pad is standard height on factory tall deck intakes, which means that a longer distributor is NOT necessary when using the factory manifold. Yes, you read that right-- there is a lot of disinformation out there saying otherwise. All standard GM HEI and points distributors will fit these engines (although camshaft gear or oil pump drive shaft modifications may be necessary).

These manifolds have a unique two-thermostat design for a higher coolant flow. Both thermostats are identical, fully open at 180 degrees. When fully opened, a restrictor plate on the bottom of the thermostat descends to plug the bypass opening and force coolant through the radiator only. If these special thermostats are not used, the bypass will remain open at operating temperature and not all coolant will pass through the radiator. Because of the dual thermostat design, these intakes obviously use a unique thermostat housing as well.

Probably the hardest part of using the stock intake manifold with a standard water pump is adapting the huge 1.75in. radiator bypass down to fit the 3/4in. inlet in the pump. Although this reduces the bypass flow, it does allow use of a non-industial pump and its easier to find (and cheaper) associated parts like standard radiator hoses, etc. One way to solve this issue is to use a 1.75in. elbow from the intake, then adapt down the other end to fit the pump with standard NPT threaded fittings to create a 1.75in. to 3/4in. adapter. Some adapters can by purchased, but they are generally too long to fit the tight space of the elbow.

Note that the intake carburetor ports are all the same size, and intended for use with the specific Holley carburetor that was used from the factory. If a carburetor with larger secondary plates is used, an adapter plate must be used between the carburetor and the intake manifold to allow the throttle plates to open completely. Make sure to measure and check these carefully before installing your specific carburetor.

There are two different thermostat housings available; one at an approximate 45 degree angle forward, the other nearly straight up. The former was used on smaller trucks with lower radiators, while the straight model was mostly used on trucks with the high mounted water pump and radiator (although this is not always the case). Both use the same gasket and hose size. For water pump differences see here: 366/427 Water pumps

Standard big block manifolds may be used on these engines, however spacers must be used between the heads and manifold to make up the larger gap. A longer distributor shaft or adjustable slip-ring collar shaft may also have to be used with a standard big block intake manifold.

Generally unless changing the application of the engine, a standard big block intake manifold is not necessarily desireable unless other changes are being made. The thermostat bypass to the water pump is different, as well as water flow changes. Changing the intake may also change the RPM power characteristics of the engine based on intake runner length, etc.

Incomplete list of tall deck intake manifold casting numbers (list currently being researched):

3856292 2 bbl carburetor

354463 4 bbl square bore

354488 4 bbl square bore

840223 4 bbl square bore

3917225 4 bbl square bore

3817226 4 bbl square bore

14081038 4 bbl square bore (oil splash pan)

10069272 2 bbl TBI (1998, no oil splash pan)

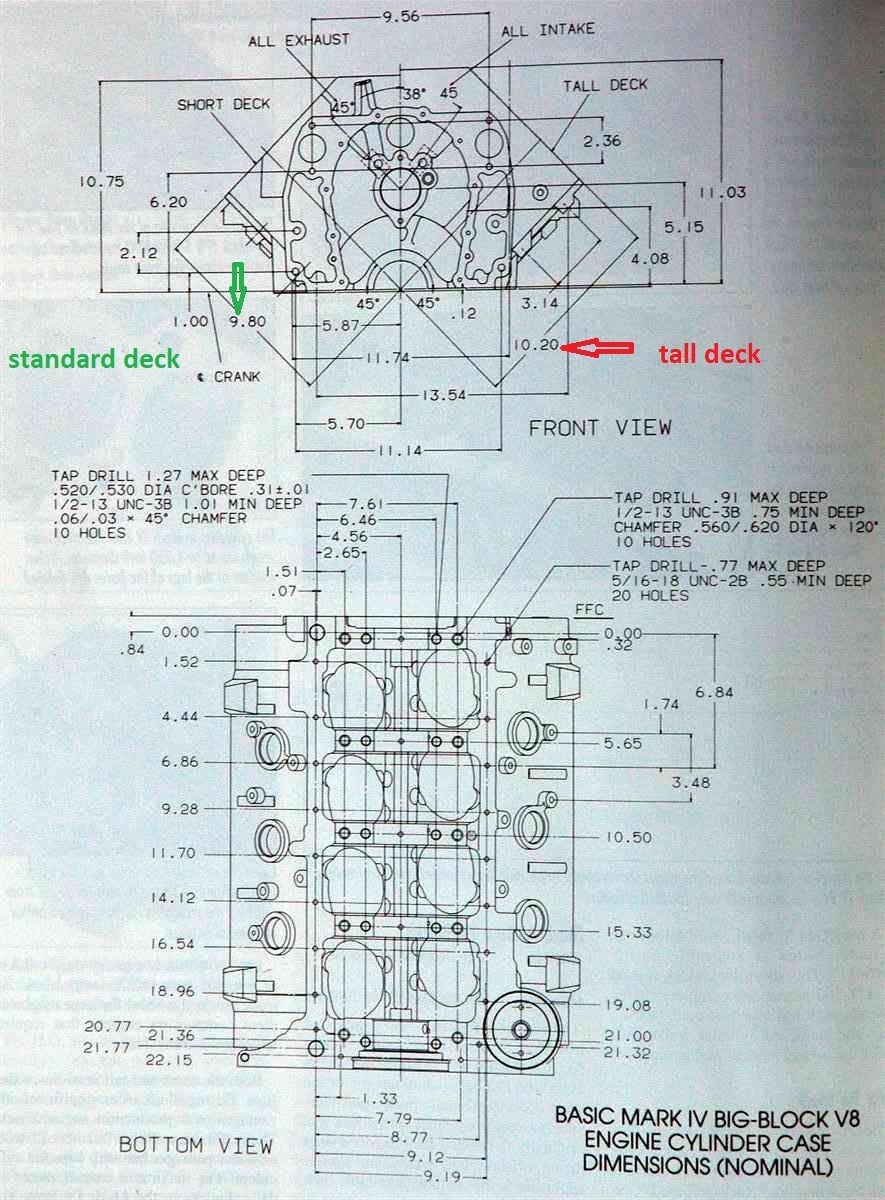

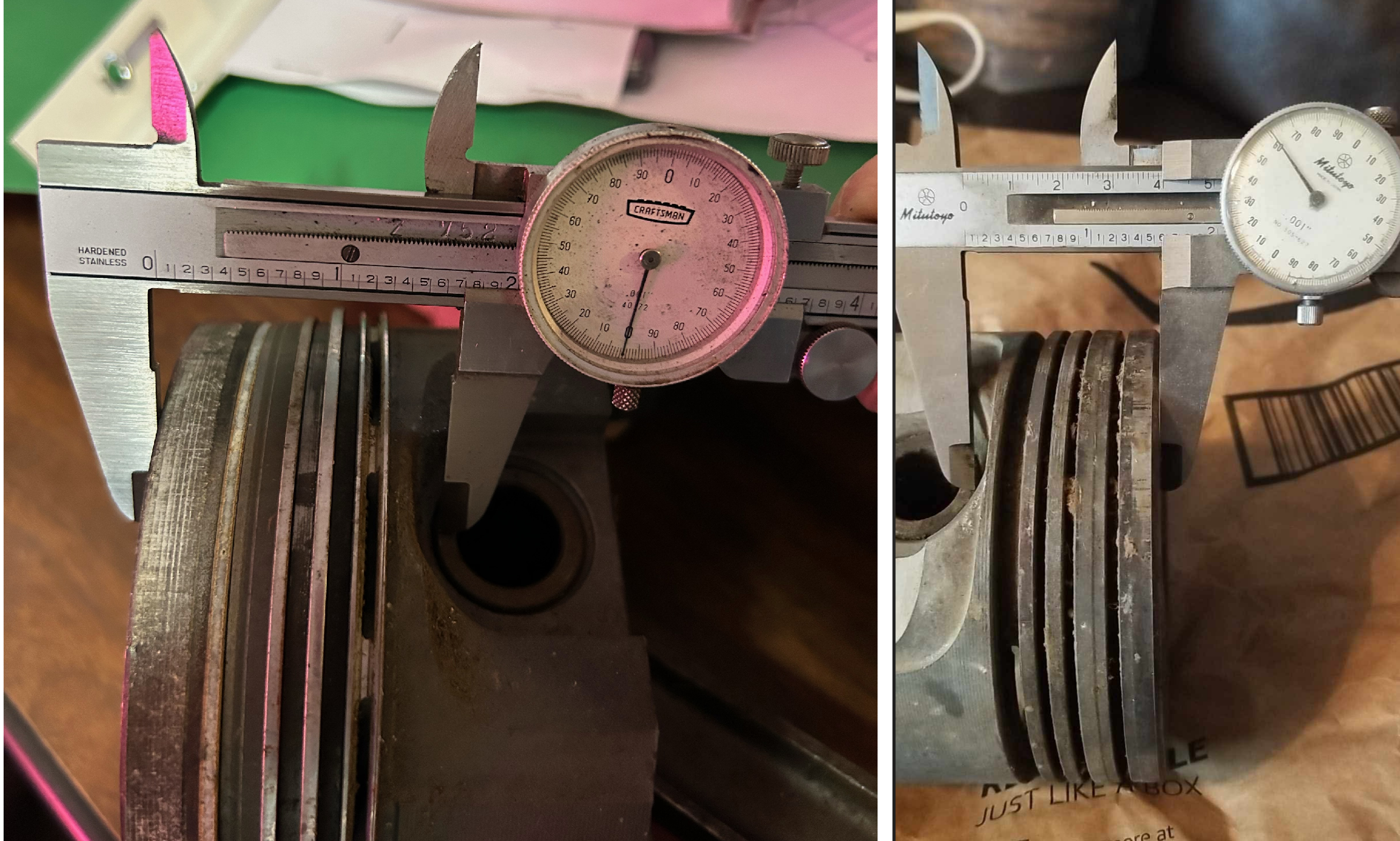

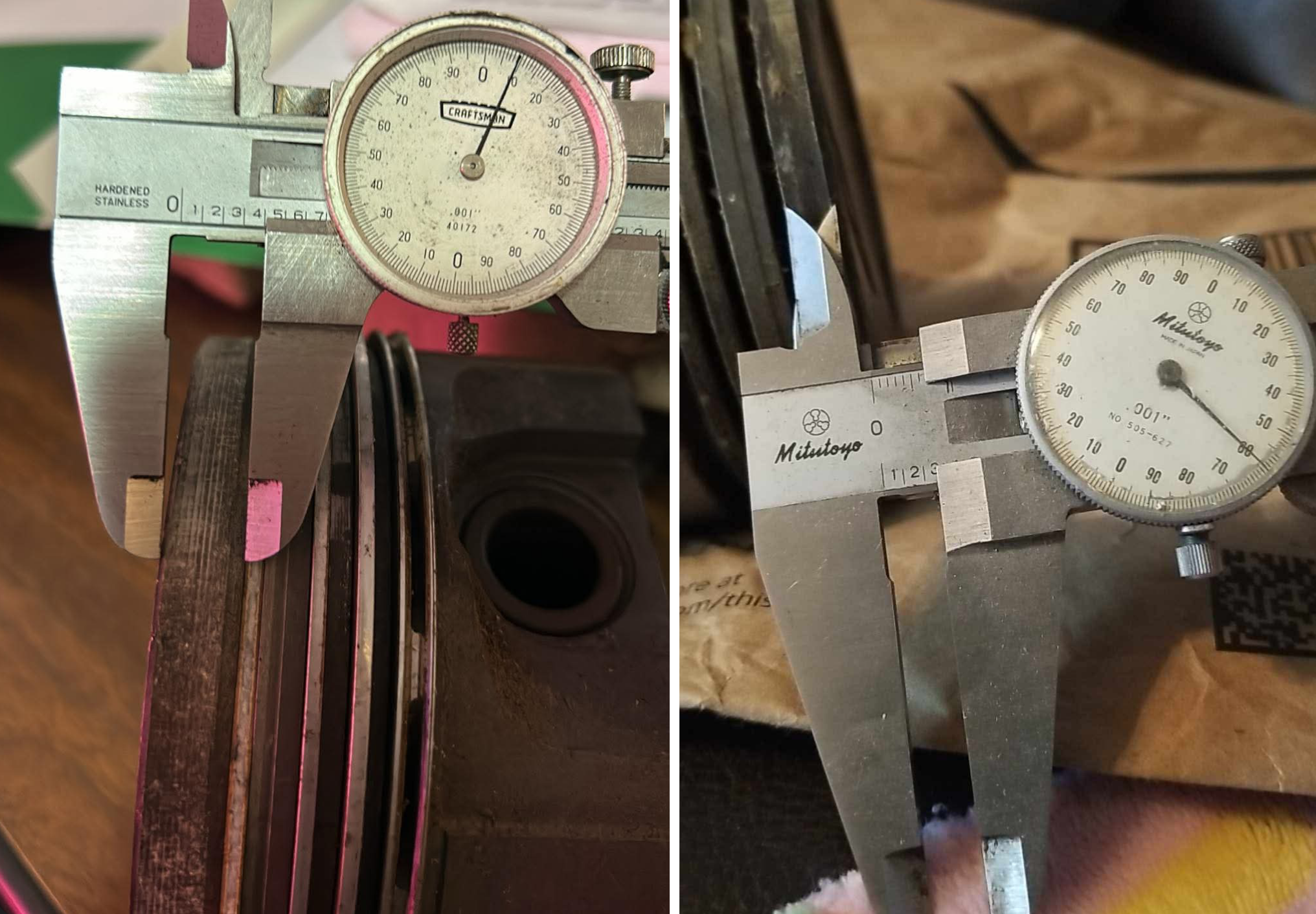

Tall deck engines and standard deck engines are not actually that different externally. The deck height is slightly taller, which allows a taller piston with an extra ring. The crankshaft stroke is unchanged. The taller deck means the cylinder heads are set slightly further apart, but spacer kits are made to use aftermarket intake manifolds. Accessory bracket problems due to this distance change can be overcome by using brackets for each accessory that only mount to the head or block respectively. When retrofitting a tall deck in place of a standard deck, the exhaust manifolds will also be slightly further apart. Early tall decks came with a factory cast-iron one piece crankshaft pulley/damper assembly. This can also be replaced with standard parts (or the later two-piece pulley) if desired, but the factory pulley is deep, four groove, and very useful, although heavy. This pulley does necessitate the use of either a short nose water pump or the factory pump.

The factory tall deck manifolds are made for use with the front engine mount, not the 'clamshell' mounts. While the driver's side manifold will work with either, the passenger side manifold will be in the way of the 'clamshell' style mount. If using 'clamshell' style mounts the passenger exhaust manifold must be replaced.

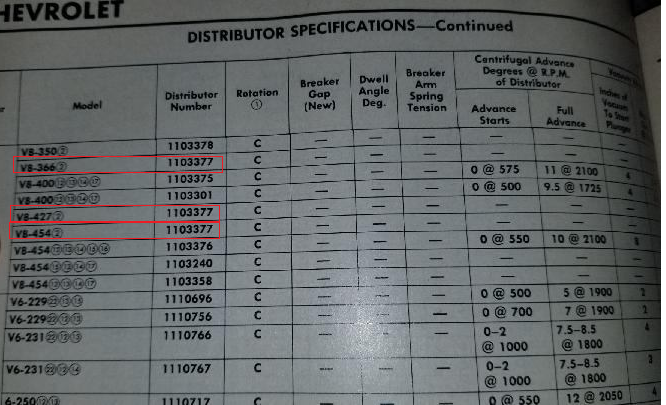

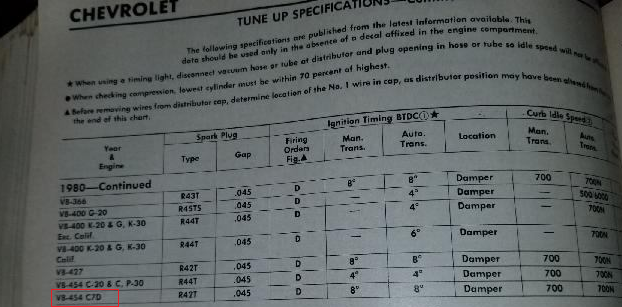

Early points style distributers can be converted to later HEI (High Energy Ignition) style distributors by switching the oil pump drive shaft. Removing the factory distributor will remove governor functionality, so be aware of this. But probably if you're reading this, then the factory governed carburetor is long gone anyway. Early distributors use a hex style distributor drive, while standard HEI is a slot drive. In order to convert, either the distributor gear/shaft (as appropriate) must be swapped to the new distributor, or the oil pump must be removed and the drive shaft changed to the newer slot drive style. The outer cases/castings of the two distributors are fully interchangeable, and use the same dimensions from the intake manifold on down (obviously the tops from the intake manifold on up are different). If the original factory engine lifting points are still in place, the rear one may interfere with the vacuum advance canister of later HEI style distributors as the factory points distributor is a smaller diameter overall. This can be easily bent slightly out of the way to allow fitment. Other than some wiring harness changes to adapt to the HEI ignition, this is all that is required for the conversion.

Functionality: In operation, when the engine reaches its governed speed of 4000 RPM, the centrifugally-operated spinner valve in the distributor will close, thus applying a vacuum on the carburetor actuator diaphragm which in turn acts to close the throttle valves. The overspeed warning switch in the spinner governer vacuum line also senses this vacuum and lights a warning to alert the driver. The distributer is not specific to the governor system, but it does have some add-ons. There is a diaphragm on the carburetor which uses vacuum to keep the throttle shaft engaged with the throttle linkage. If the engine overspeeds, there is a valve inside the distributor that shuts and pulls the throttle shut. Basically, the distributor will allow air to pass through it until the engine hits the governed speed. Once vacuum builds up in the line to the carburetor, it will pull the throttle plates closed; otherwise the plates are spring loaded against the throttle linkage.

The governed speed is 4000 RPM no-load, or 3800 RPM full-load. Initial overrun allows for 150-250 RPM before settling to governed speed.

The vacuum determination is made at the distributor based on the rotation speed of the shaft and flyweights, with only the one vacuum line linking distributor and carburetor. The carburetor is a special Holley unit with the large assembly on the passenger side limiting the throttle based on this vacuum input. The rest of the carburetor is mostly standard Holley, but obviously the throttle linkage is different to allow the governor functionality. Both a vacuum operated mechanism on the carburetor itself and electric over vacuum system were used, depending on year, but all systems used a vacuum output from the distributer.

There is only a mechanical advance for timing; no vacuum advance. This system was used on industrial engines only, so a vacuum advance offered little benefit. There is usually a vacuum operated electrical switch in the circuit to turn on an overspeed warning light on the dashboard. Most of these distributers have a 'T' connection off the bottom of the carburetor with one side to the carburetor governor, and the other to the electrical switch. There will also be a breather canistor off the side of the distributer.

To check the mechanical advance: Remove the distributor cap and grab the top of the distributor where the rotor attaches and turn it clockwise. It should turn fairly easily with the only resistance being the pressure from the springs on the flyweights. If it doesn't turn easily or return with the spring pressure, the mechanical advance is hanging up. This can cause low power. It's fairly easy to fix; just remove the distributor, remove the roll pin and drive gear, slide the shaft out of the distributor, take the weights and springs off, slide the lower piece with the point cam off the shaft (will take some lubrication and working back and forth, especially if completely stuck). Clean up both pieces with some emery cloth, lube and reassemble everything in reverse order.

If you wish to switch to a non-governed carburetor but do not want the hassle of changing the distributor, the vacuum 'T' at the distributor base may be removed and the port plugged. Since the distributor is mechanical advance with points, it requires no connections other than the standard electrical.

Other than the more complicated carburetor mechanisms, the governor system is fairly simple and straightforward. Usually problems associated with standard distributor, ignition, or carburetor problems will be erroneously blamed on the governer. Before suspecting the governor system, make sure the other systems have been eleminated.

The commercial/industrial big block engines came with a larger pan. One reason is the increased clearance for it in the larger engine compartments of bigger trucks, or in stationary engine applications like generators. Another reason is the better cooling and oil life given by an increased oil capacity. Any pan compatible with the proper generation of engine block will fit in its place. The larger pan may not clear some crossmembers in standard cars or trucks.

Note: for oil itself, see here.

Not all the engine oil gets sent through the filter on every pass through the system. As noted in the oiling section, the pump feeds BOTH the filter and the rear crankshaft main journal simultaneously. While this ensures the primary system is always pressurized, it also presents an issue in terms of longevity if the oil becomes contaminated. Even with a new filter it is still possible for particles or contamination to pass into the galleries in the engine. Also if the filter becomes too heavily clogged or restricted, the bypass will open and allow even more unfiltered oil to bypass the filtration system. While most contamination will eventually be filtered out (given a good condition filter), it may pass through the engine one or more times first.

To try to prevent this contamination condition besides the filter, there is also a screen on the pump pickup inside the pan. This restricts the maximum particle size allowed to pass into the system, while not reducing pressure in the system.

Another line of defense, and one we highly recommend, is a magnetic pickup in the pan. Pan drain bolts can be purchased with magnetic tips to attact and hold ferrous metal particles that enter the oil. These can be cleaned and examined with every oil change. We also recommend putting a seperate larger magnet inside the pan itself to allow for a larger and more efficient collection over time than merely just the drain bolt will allow.

A highly recommended option is also to use a larger filter. The filter capacity can easily be doubled from one quart to two, which adds both filtration capacity and more oil to the entire system for better heat transfer. While they are significantly longer, on the factory tall deck engines there is plenty of height clearance and room.

We include this section because although the oil flow is the same as a standard big block engine, there seems to be some confusion on the internet about the order and priority in which internal parts get oiled. We have simplified it here for those who may want a better understanding of both lubrication order for parts and oil flow in the system.

The tall deck engines use the same oiling as the standard Chevy big block engines. Oil is pulled from the bottom rear of the oil pan by a mechanical gear driven pump and forced upward into the oil passageways inside the engine.Oil then feeds to a main passageway which feeds both the oil filter/cooler (if equipped) AND crankshaft. Note that not all the oil gets filtered in each pass through the engine as some will always feed the crankshaft main journals first, and start its way through the engine. This is a safety feature to ensure that the crankshaft journals are always pressurized regardless of filter condition and oil cooler condition. The return from the filter/cooler also feeds back into a gallery that feeds both the crankshaft and camshaft simultaneously.

Oil feeding the rear main crankshaft journal then works its way forward to the rods and mains in order, back to front. Bleed oil from this system feeds the camshaft main journals above as it passes, and the passageway at the rear of engine upwards that feeds the top end. This rear vertical gallery also passes by the distributor, feeds around a groove/hole in the distributor shaft casing, and continues upwards to the lifters and pushrods. This is why upper end oiling is impeded if the distributor casing is either not aligned correctly or not in place at all during pre-oiling.

At all points of clearance in the system, such as journal edges or lifter bores, small quantities of oil will bleed out and return to the pan, also oiling other internal parts of the engine through drip or spray oiling.

The valve mechanism is lubricated by oil which comes up the pushrod center-bores, spraying and dripping throughout the top of the cylinder head to lubricated the valve stems, springs, rockers, and pushrods. This oil then returns to the pan by dripping through passageways down through the engine.

Note that the camshaft lifter lobes do not have a directly pressurized application of oil. Instead the lobes are lubricated by both drip oil from the cylinder heads returning to the pan, and oil bleed from the pressurized lifter bores which gravity pulls down to the lobes. This is why on initial startup of a new camshaft or lifters, it is vitally important to use pre-lubrication before starting the engine.

The timing chain and fuel pump rod also are not pressurized, being lubricated by drip/spray oil from a horizontal oil gallery which passes to the front of the engine from the rear vertical channel above the pump that also feeds the valvetrain.

For an in-depth examination of oil clearances, we include the charts below. Note that very very tight clearances are not necessarily better, but rather there is a 'sweet spot' at which mechanical clearances should be set to optomize oil flow and temperature. Since the shafts ride on a film of oil and should never directly contact the bearings, the load-bearing capacity should be maximized for best engine longevity. A range of approximately two to three-thousandths of an inch clearance works best for load-bearing, temperature, and oil flow, since without oil flow the rest of the engine will not be lubricated well. Clearances that are too tight OR too loose will shorten engine lifespan.

The oil pressure is not as relevant since that does that reflect the amount of oil passing through the system, and different parts of the system will naturally have different pressures with the lowest pressures being at the top end of the engine on the far end of the oiling system, and the highest pressures being directly after the pump at the crankshaft and camshaft journals. It is possible to have high pressure in the oil system while still having an inefficient or partly inoperable lubrication system. This is why a high oil pressure reading on a dashboard guage does not necessarily give a good idea of overall lubrication system condition.

Note that while both high pressure or high volume pumps are available, raising the system pressure alone is not a good idea usually as oil seals are only rated for certain pressures. Exceeding these pressures regularly will result in oil seepage on the exterior of the engine, as well as excessive seal wear and leakage over time. Also, raising the oil pressure does not necessarily result in more oil moving through the system, and may be detrimental in terms of oil cooling as more pressure equals more heat. High volume pumps can make up for an excess of engine clearances, pushing more oil through to make up for what is lost as it leaks from these excessive clearances more than usual. However, installing a high pressure or high volume pump can still only move as much oil through the system as clearances and gallery sizes allow. Any excess oil that cannot be driven into the system by the pump merely returns to the pan through the bypass or clearances.For an idea of how the effect of heat can damage oil, see the chart below.

Note how the oil life drops dramatically over the standard operating range of 190 degrees. Overheating an engine only one time can reduce the lubricating ability of the oil to almost nothing, as the heat breaks down the oil chemically and removes its lubricating properties.

The factory tall deck cooling system has some significant differences over the standard Chevrolet big block. Capacity is increased, the system is designed to move more coolant (see water pumps), and the coolant bypass before the thermostats is different.

The coolant bypass in the standard big block engine is always active, unlike the tall decks. A small hose runs from just before the thermostat to the pump return, making sure that coolant always circulates through the engine even when the thermostat is closed. In the factory tall decks, the thermostats opening will cut off the coolant flow to the bypass by dropping down a cap attached to the bottom of the thermostat and mostly closing off the passage to the bypass hose.

The big difference between the tall deck and standard can be seen in the graphic above. Coolant does NOT flow through the bypass in the tall deck when the thermostat is open. In cases where the wrong thermostat is installed this can lead to overheating, as too much coolant will bypass the radiator as the path of least resistance. Make sure the correct thermostat is installed for your application. The bypass is a lot larger in the tall decks, and will move a significant amount of coolant.

There are two different ways that coolant can be routed through the engine: series flow and parallel flow. Both ways usually work just fine. There may be a slight preference for parallel flow.

Series flow has the water exiting the water pump, flowing through the block to the rear, then transfering through the head gasket and into the cylinder head through two large passages on each cylinder bank at the rear of the block. The coolant then travels from the rear of the head, forward to the front of the head, into the intake manifold water passage and out past the thermostat and thermostat housing. The water cools the block first, then it cools the head. The coldest water (coming out of the water pump) is directly below the hottest water (having already picked up the heat of the block and the head) as the hot water transfers into the intake manifold.

Parallel flow has the water exiting from the water pump into the block, where a portion flows up into the head between each cylinder bank. The remainder transfers to the head at the rear of the block.

The differences in coolant routing is having (or not having) the three additional coolant transfer holes in each block deck, and three matching holes in the head gasket. The cylinder heads have passages for either system.

Be aware that gaskets that DO have the three extra holes between the cylinders often have restricted coolant flow at the rear--instead of having two large coolant transfer holes at the rear, there is only one, and it's the smaller of the two holes that remains. This is important because if you use a parallel flow head gasket on a series flow block, you can have massive overheating and there's NOTHING that will cure the problem except to replace the head gaskets with ones that don't restrict flow at the rear of the block, or to drill the block decks to allow the coolant to flow into the head between the cylinders. Here's why they can overheat: A series-flow block doesn't have the openings between the cylinders, no coolant can flow up to the head there. The gasket may only have the single, smaller opening at the rear, so the amount of water that gets through that opening is greatly reduced from what the block designers intended. The result is that the coolant flow through the engine is only a fraction of what is needed.

A series flow block can be converted to parallel flow by drilling 3 holes in each deck surface, and then using parallel flow head gaskets. Use the parallel flow gaskets as templates for locating the additional holes. There is NO modification needed on the head castings.

366/427 tall deck specifications:

Cylinder block deck height: 10.2 inches

366 standard bore: 3.935 inches

427 standard bore: 4.25 inches

crankshaft stroke: 3.76 inches

Bore spacing, center-to-center: 4.84 inches

Compression ratio: 8.0:1

Pistons: flat-topped, cam-ground, plated, aluminum casting, solid slipper-skirt design with autothermic expansion control

Piston rings: 4, all phosphate coated for durability

Top compression ring: ring face is channeled and molybdenum filled

Middle and bottom compression rings: ring faces lightly chrome-plated

Oil ring: lowermost is chrome plated cast-iron oil ring with coil spring expander

Camshaft: cast-iron, lobes induction hardened and treated

Connecting rod length: 6.135 inches

Oil filter: 2qt capacity

RPM limit: 4,500 RPM

RPM maximum sustained operation (governed speed): 4,000 RPM

Except for a few applications, most have forged crankshafts. All block castings have 4-bolt crankshaft main bearing caps.

Note that the 427 block is not an overbored 366 casting. They are different castings, with the difference being in the cores used for the cylinder bores. A 366 block cannot be bored out to 427. The cylinder walls are roughly equivalent in thickness for the same heat dissipation. This gives the 366 an ever so slight coolant capacity increase also.

First offered in 1966, the 366 engine had a compression ration of 8.0:1 and was offered in two versions. A medium duty version, and a heavy duty version with a higher net power rating and "certain premium quality components which are required for maximum durabilty in heavy-duty operations". Which components GM was referring to we are not exactly certain, although it could have been such things as the different between a cast or forged crankshaft, and a gear-drive camshaft or chain-drive. This medium-duty/heavy-duty difference was offered in other years also, which GM is also unclear about in much of their documentation, but we assume this is why some cast crankshafts and other less regarded parts can be found in some original factory versions of these engines.

Below is the power chart for the 1966 366 cubic inch, 2 bbl heavy-duty engine:

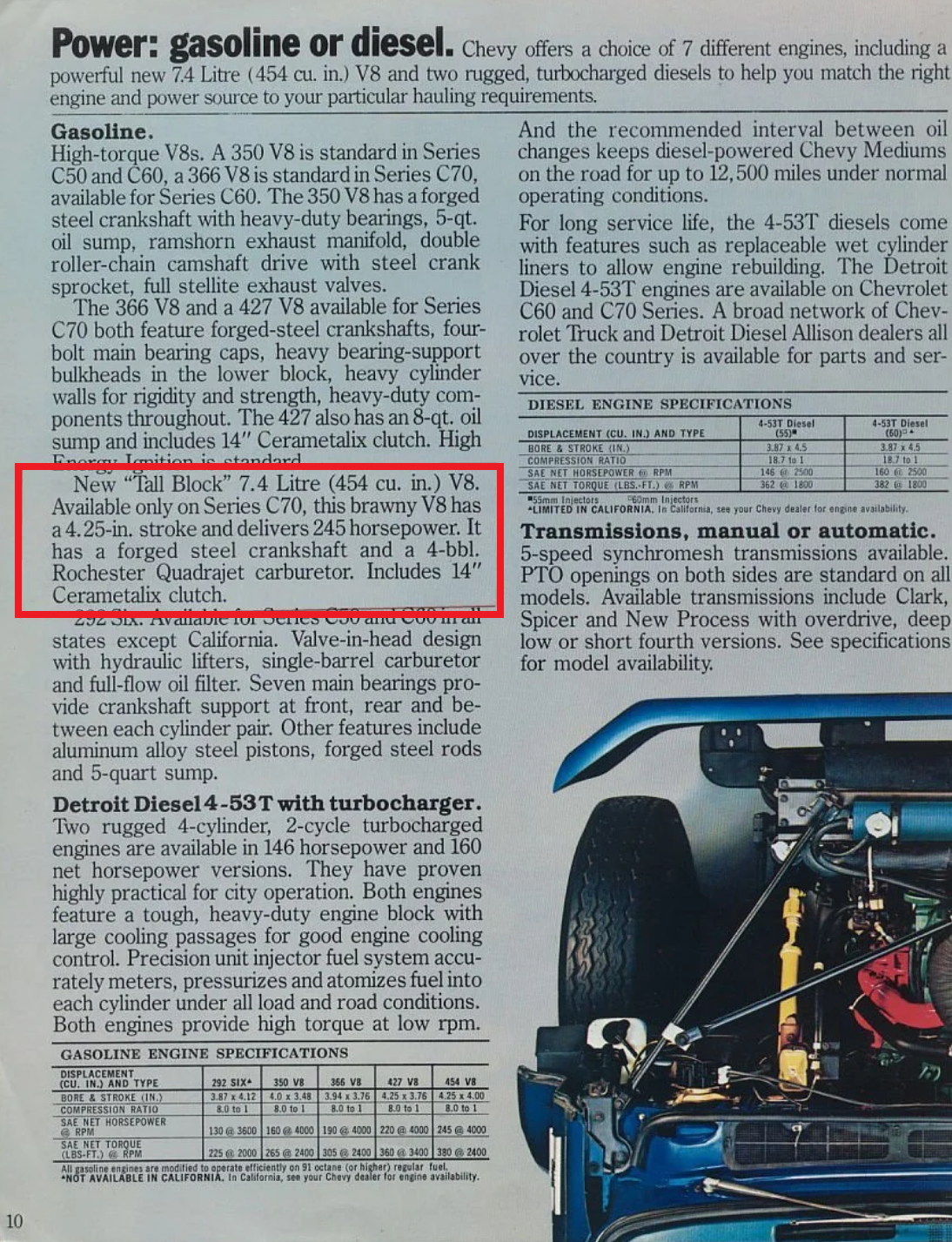

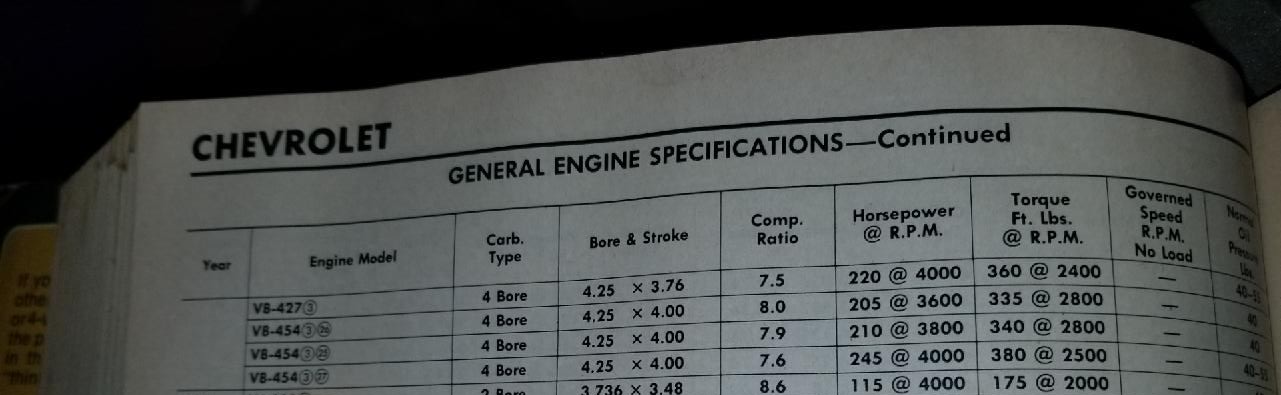

454 tall deck specifications:

Cylinder block deck height: 10.2 inches

standard bore: 4.25 inches

crankshaft stroke: 4.00 inches

Bore spacing, center-to-center: 4.84 inches

Compression ratio: 7.6:1

Pistons: flat-topped, cam-ground, plated, aluminum casting, solid slipper-skirt design with autothermic expansion control

Piston rings: 4, all phosphate coated for durability

Connecting rod length: 6.135 inches

Oil filter: 2qt capacity

All have forged crankshafts. All block castings have 4-bolt crankshaft main bearing caps.

All block castings have 4-bolt crankshaft main bearing caps.

All bock casting decks are designed .4" higher than a standard GM big block deck.

Note that the 427 block is not an overbored 366 casting. They are different castings, with the difference being in the cores used for the cylinder bores. A 366 block cannot be bored out to 427. The cylinder walls are roughly equivalent in thickness for the same heat dissipation. This gives the 366 an ever so slight coolant capacity increase also.

Engine block factory tall deck casting numbers:

[Some casting end dates have conflicting source info, we have done our best to validate where possible]

---*ending 470 --427 cubic inch, approx. 1980-1990 (84-85 certain, complete casting number/dates unknown), head castings (1985+): 052 or 359 or 772 or 875 or 328 or 765 or 771 or 772 or 865

---340220 --427 cubic inch, 1968-1985 (possibly to 1990), head castings (1985+): 052 or 359 or 772 or 875 or 328 or 765 or 771 or 865

---364776 --427 cubic inch, 1974-1985 (possibly to 1990), head castings (1985+): 052 or 359 or 772 or 875 or 328 or 765 or 771 or 865

---364779 --366 cubic inch, 1968-1985 (possibly to 1991), head castings (1980+): 052 or 219 or 328 or 393 or 771 or 864

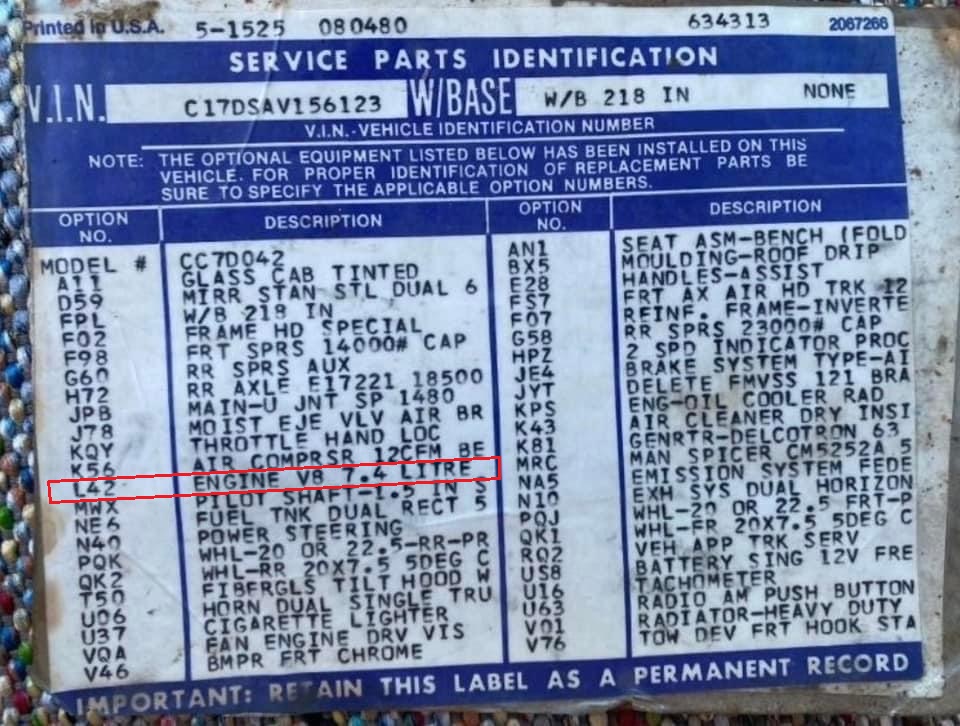

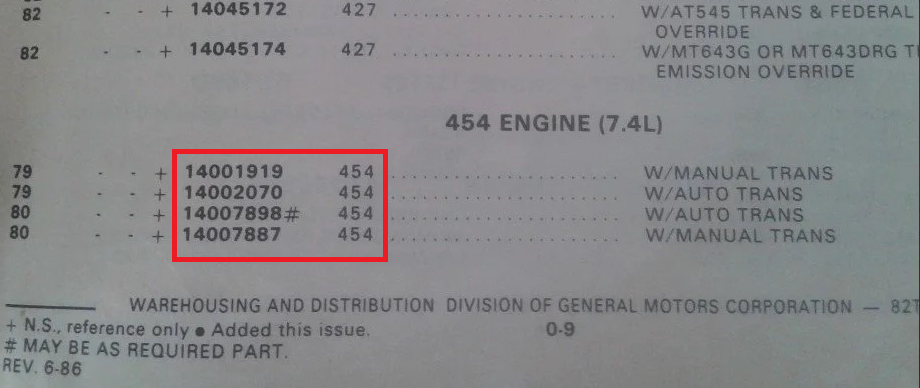

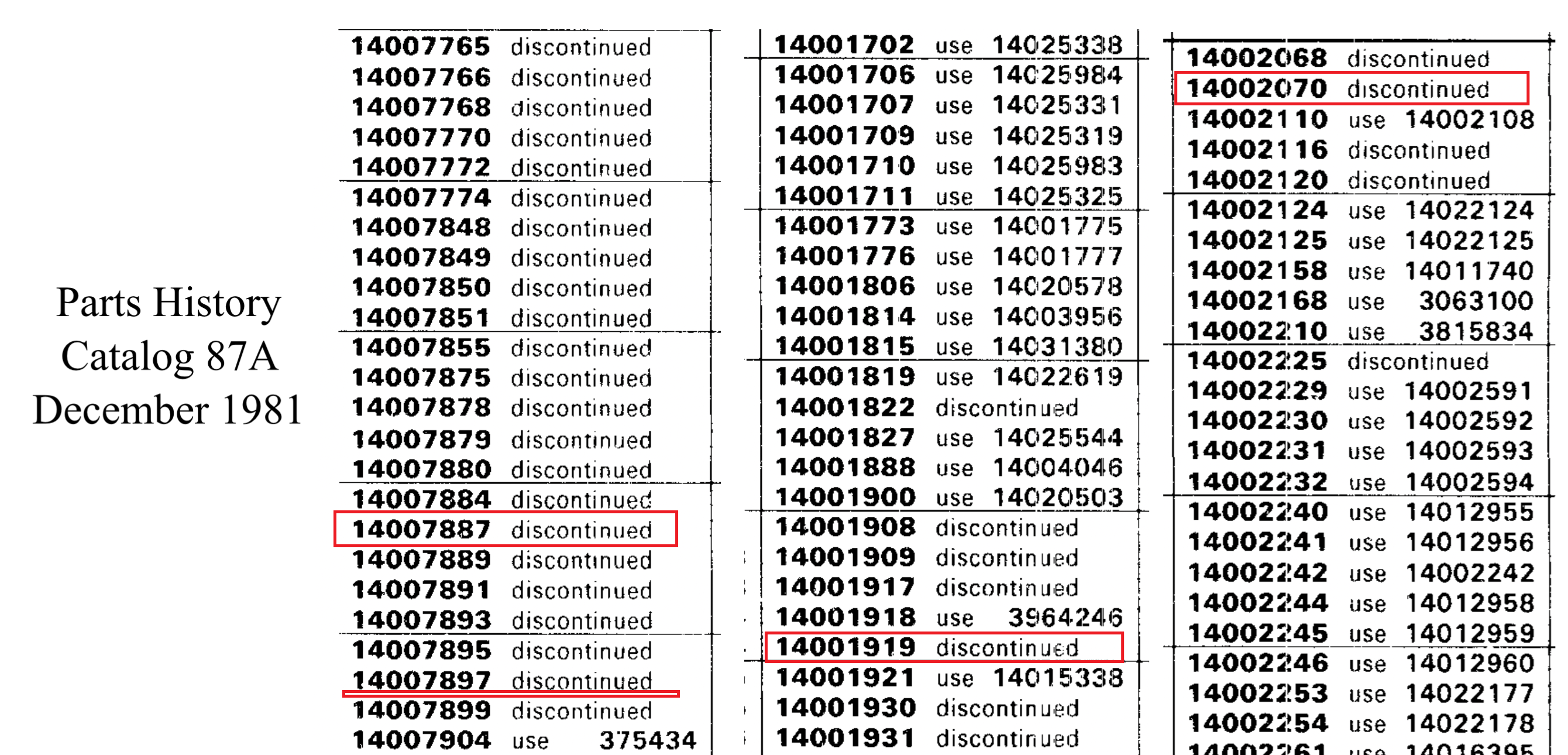

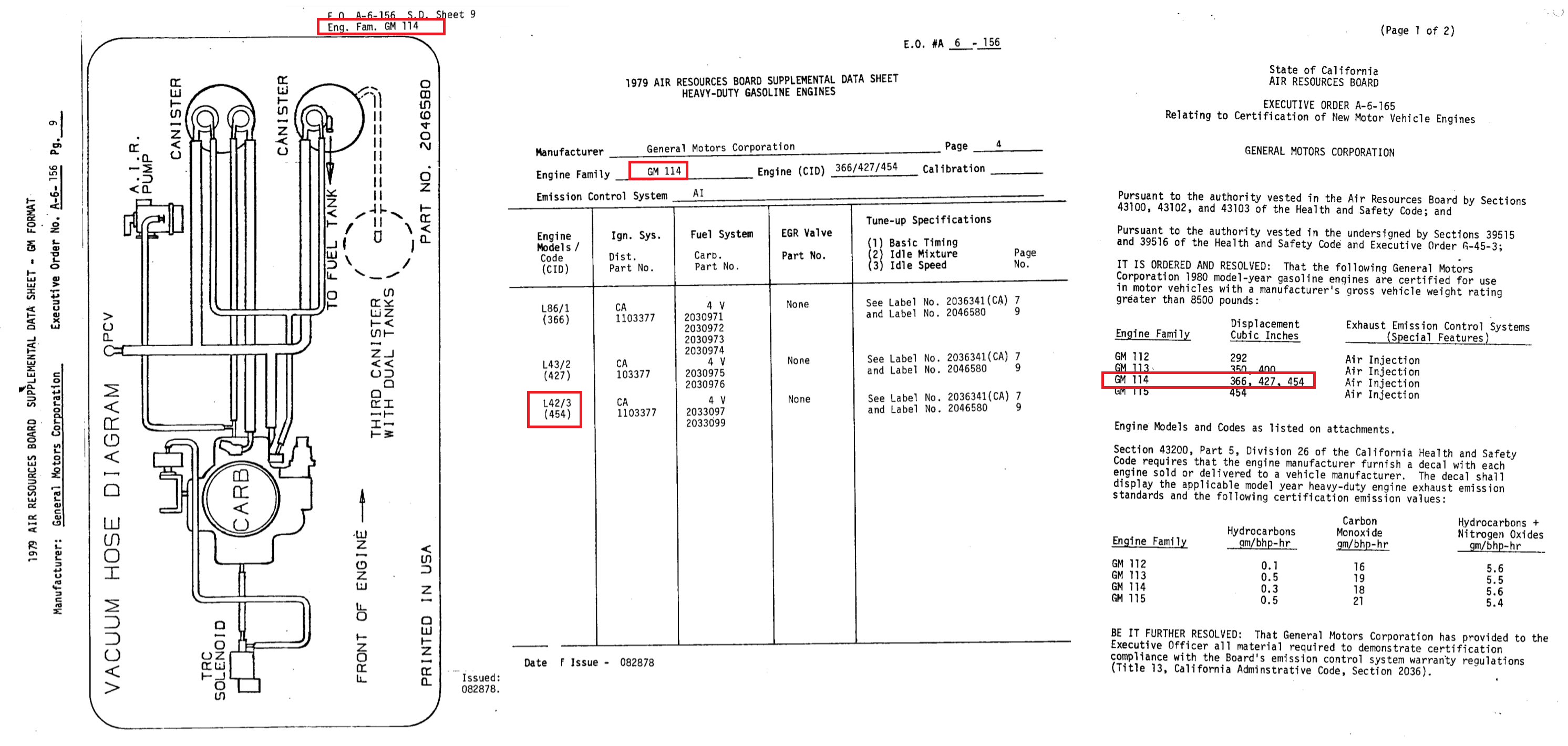

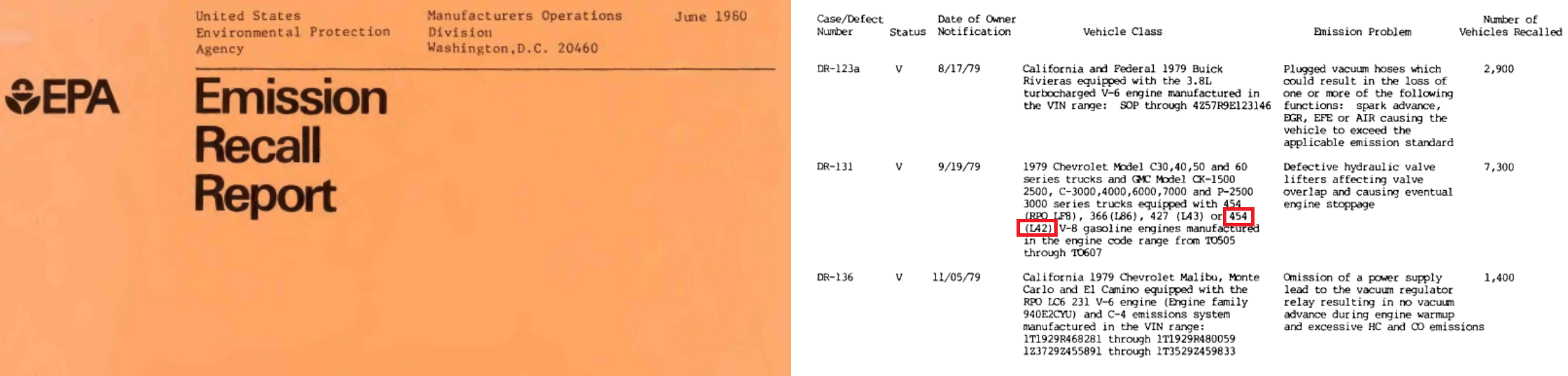

---473478 --427 cubic inch 1977-1985 (possibly to 1990), or 454 cubic inch (1979-1980 only), head castings (1985+): 052 or 359 or 772 or 875 or 328 or 765 or 771 or 865

---4734 8 --same as 473478 but on a 454 stamped block (note we have only one recorded instance of this block casting number with a blank space. It appears intentional but might not be.)

---3782870 --427 cubic inch, 1968-1976

---3824553 --366 cubic inch, 1966-1967

---3855977 --366 cubic inch, 1966-1973

---3904354 --366 cubic inch, 1966-1976

---3916319 --366 cubic inch, 1968-1980

---3925521 --427 cubic inch, 1968-1985 (possibly to 1991), head castings: 052 or 359 or 772 or 875 or 328 or 765 or 771 or 772 or 865

---3937724 --366 cubic inch, 1968-1985 (possibly to 1991), head castings (1980+): 052 or 219 or 328 or 393 or 771 or 864

---3937726 --427 cubic inch, 1968-1985

---3955274 --366 cubic inch, 1968-1976 (possibly to 1991), head castings (1980+): 052 or 219 or 328 or 393 or 771 or 864

---3955276 --427 cubic inch, 1968-1973

---3969852 --366 cubic inch, 1968-1984 (possibly to 1991), head castings (1980+): 052 or 219 or 328 or 393 or 771 or 864

---3969858 --427 cubic inch, 1968-1984

---3999293 --366 cubic inch, 1968-1991, head castings (1980+): 052 or 219 or 328 or 393 or 771 or 864

---3999294 --427 cubic inch, 1968-1991

---10069282 --366 cubic inch, 1990-1991, Mark IV, head castings: 052 or 219 or 328 or 393 or 771 or 864

---10069284 --427 cubic inch, 1990-1991 Mark IV

---10114183 --366 cubic inch, 1991-1996, VIN: P, FI,Naturally Aspirated, Gas, head castings 140 or 933, (note: these engines may have cast, not forged factory crankshafts)

---10114184 --427 cubic inch, 1991-1996, VIN: M, FI, Naturally Aspirated, Gas, head castings 140, (note: these engines may have cast, not forged factory crankshafts)

---10237298 --366 cubic inch, 1996-1998, VIN: P, FI, Naturally Aspirated, Gas, head castings 140 or 933, no fuel pump boss)

---10237299 --427 cubic inch, 1996-1998, VIN: M, FI, Naturally Aspirated, Gas, head castings 140, no fuel pump boss

---12550311 --366 cubic inch, 1996-1998, VIN: P, FI, Naturally Aspirated, Gas, head castings 140 or 933, mechanical fuel pump boss

---12550312 --427 cubic inch, 1996-1998, VIN: M, FI, Naturally Aspirated, Gas, head castings 140, mechanical fuel pump boss

Regular Production Option (RPO) codes relating to casting numbers:

---LS0 (1990-1998) used blocks: 10237298, 12550311, 10114183

---L86 (1980-1991) used blocks: 364779, 3937724, 3969852, 3999293, 3955274, 10069282

---LR0 (1991-1998) used blocks (note some overlap with L43): 10114184, 10237299, 12550312, 340220, 364776, 473478, 470, 3925521

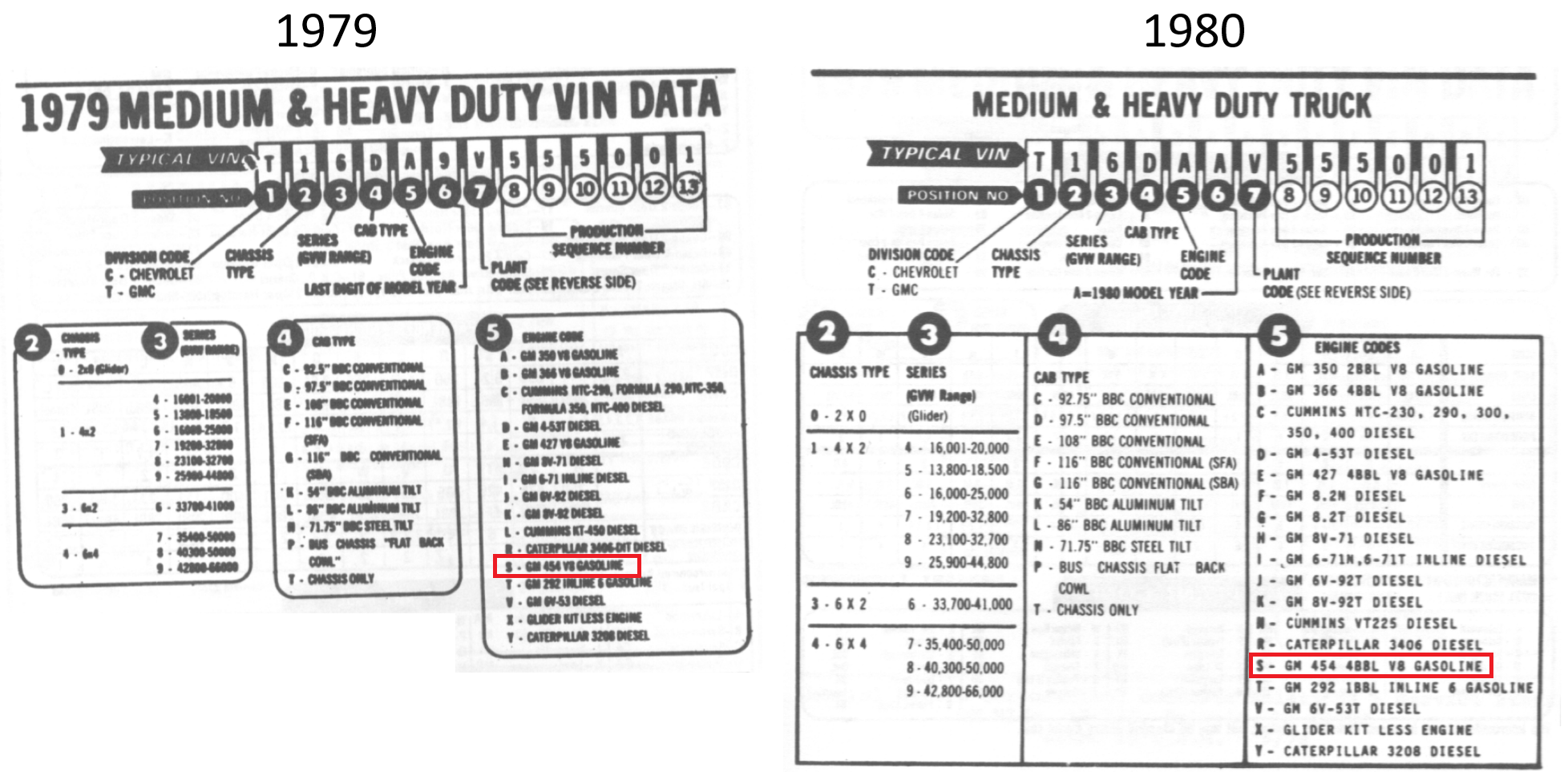

---L42 (1979-1980) used block: 473478

---L43 (1980-1990) used blocks: 340220, 364776, 473478, 470, 3925521

Except for a few applications, most have forged crankshafts.

All main journals 2.7488-2.7495", all rod journals 2.20", all strokes 3.76" except 454 at 4" (see 'tall deck 454').

Crankshaft factory casting numbers definitely (or possible as noted) issued in 366T/427T engines:

Where casting end date sources have conflicting information, (19--?) is used after end date.

'Possible' means that although used in standard big blocks, usage in tall decks is unconfirmed.

[Please note not all data may be confirmed, if you have photos or contradicting info please contact us!!]

6223 --366/427 cubic inch, 1966-1990, forged steel

7115 --366/427 cubic inch, 1966-1990, forged steel

7416 --454 cubic inch, used 1979-1980, forged steel (see 'tall deck 454')

7463 --454 cubic inch, usage uncertain, forged steel (see 'tall deck 454')

9115 --366/427 cubic inch, 1966-1990, forged steel

3804816 --possible, usage uncertain, 1961-1976, nodular iron

3856223 --possible, usage uncertain, 1965-1971, forged steel

3863114 --possible, usage uncertain

3863144 --366/427 cubic inch, 1965-1975 (1966?-1985?), forged steel

3874874 --366/427 cubic inch, 1965-1975, forged steel

3879621 --possible, usage uncertain, forged steel

3882841 --possible, usage uncertain, forged steel

3882842 --366/427 cubic inch, forged steel

3882849 --366/427 cubic inch, forged steel

3887114 --possible (unlikely), usage uncertain, forged steel

3904815 --366/427 cubic inch, 1965-1975 (1976?), nodular iron

10114186 --427 cubic inch, 1991+, forged 1053 steel

10114187 --366 cubic inch, 1991+, cast

10114189 --427 cubic inch, 1991+, cast

Note on balancing:

Tonawanda balanced engines differently than what would happen at your local shop. Pistons and rods were weighed and sorted. Lighter pistons were mated to heavier rods. Crankshafts were balanced to a spec that included the weight of the piston/rod assemblies with the damper and flexplate/flywheel weight factored in. They did not balance to a specific gram scale like most machine shops. Because of this, if anything is changed in the assembly the factory balance will then be off. To compensate for this the assembly must be balanced instead using the correct bob-weights for the new assembly weights.

Also because of this balance method, when balancing one of these crankshafts using a specfic gram scale only, the balance may appear off. So keep in mind when using one of these crankshafts in a different spec engine, such as using one of these in a standard deck engine where the pistons/rods are all different, the crankshaft may have to be completely rebalanced and may appear very 'unbalanced' relative to another crankshaft.

Please note that we have tried to come up with a comprehensive camshaft list of specification by year, but quickly abandoned that due to a lack of good information. Then notes we include here are gleaned from the little data we can locate, and should not be taken as gospel.

Any manufacturer or part numbers other than GM numbers are reference only from what we have been able to glean MIGHT have been the stock setup. Use these numbers for general reference only as they may not be 100% accurate.

366:

1966: Hydraulic flat followers; .050 Duration-204/214; Cam Lift-.280/.295; Lobe Center-107/117.

1983: Melling CCS-31-- Hydraulic Flat Tappet, Exhaust Duration: 269.0, Intake Duration: 269.0, Exhaust Duration at .050 inch Lift: 193.0, Exhaust Valve Lift: 0.399, Intake Duration at .050 Inch Lift: 193.0, Intake Valve Lift: 0.399, Exhaust Lobe Centerline: 109, Intake Lobe Centerline: 96, Rocker arm ratio: 1.75

1983: Enginetech ECK669-- Hydraulic Flat Tappet, Exhaust Duration: 269.0, Intake Duration: 269.0, Exhaust Duration at .050 inch Lift: 193.0, Exhaust Valve Lift: 0.398, Intake Duration at .050 Inch Lift: 193.0, Intake Valve Lift: 0.398, Exhaust Lobe Centerline: 103, Intake Lobe Centerline: 103, Overlap: 63

1983: Hydraulic Flat Tappet, Exhaust Duration: 211.0, Exhaust Valve Lift: 0.398, Intake Duration: 211.0, Intake Valve Lift: 0.398, Lobe seperation angle 111

1983 366 uses a GM #330882 camshaft: intake and exhaust lift .398, 111 LSA, and 211* duration

427:

1983-1984 427 tall deck uses a GM #00330884 camshaft.

Beginning in 85-87 the 427 used GM #03963544. It would also appear that in certain applications the 366 also used this camshaft. Furthermore, this cam was also used in light duty applications.

Thanks in large part to Brandon Clayton for pointing out our lack of camshaft specifications and providing this information.

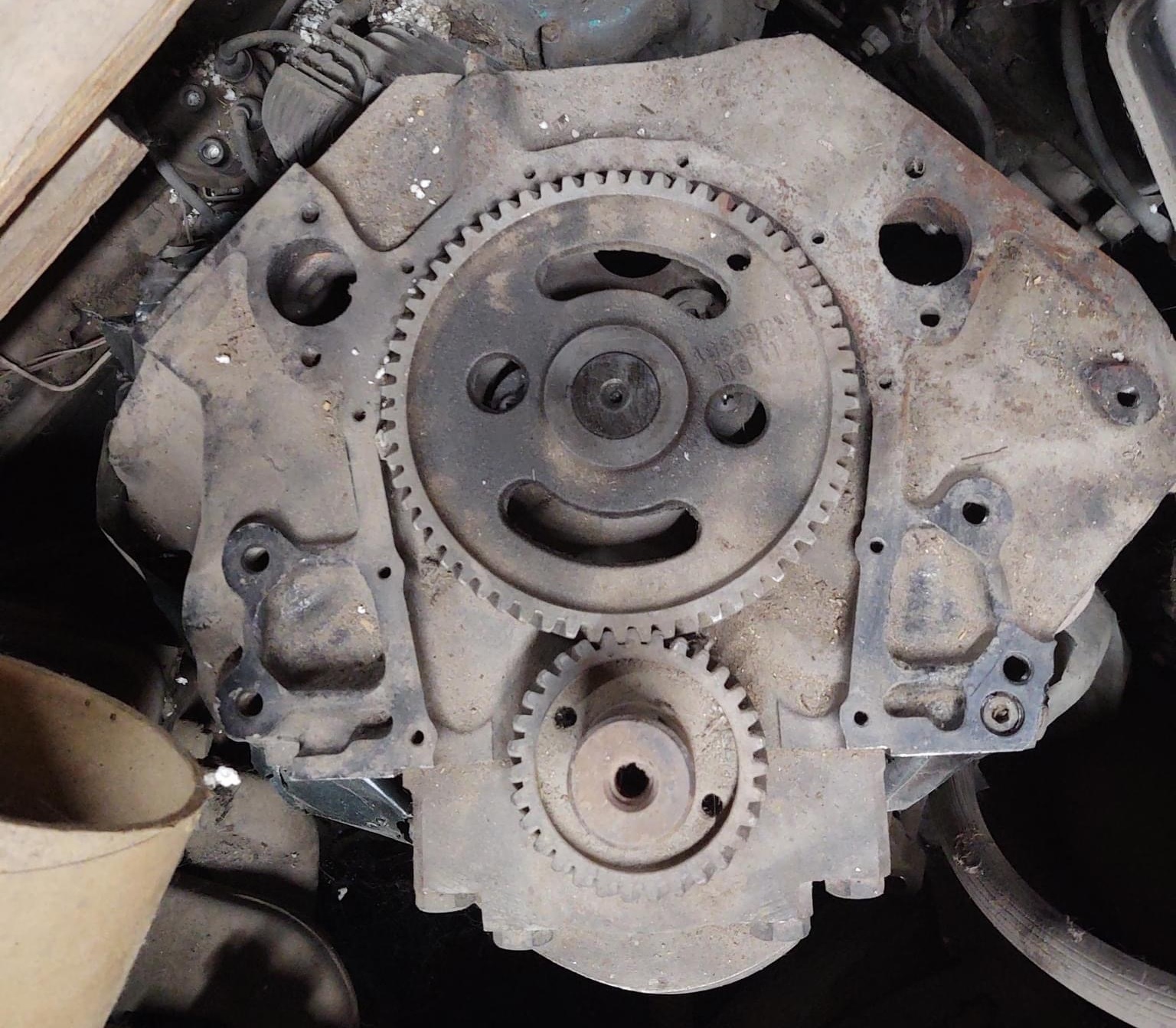

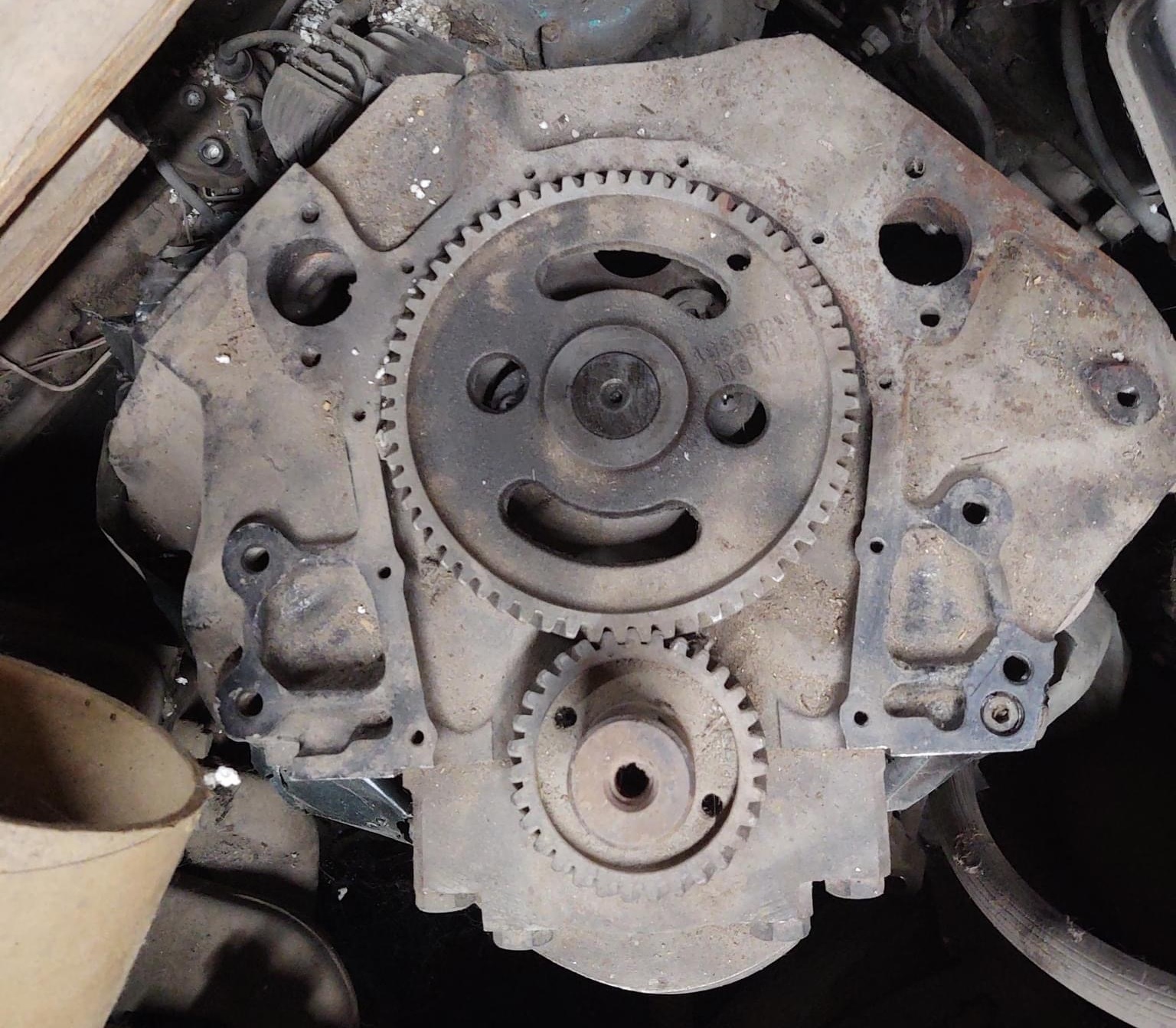

There are two different types of harmonic balancers (also called dampers) used on the industrial 366/427 tall deck engines.

Early ones used a one-piece unit with a cast-in 4-groove 'v' belt pulley. By 'one-piece' what we signify is that the unit is not seperable with bolts or fasteners; rather the outside damper section and pulley are one case piece with the inner section bolting to the crankshaft being a seperate piece with the two seperated by a rubber vibration absorbing material.

These damper/pulley combinations are very heavy (being cast-iron), and can help negate vibration with some of their weight alone acting as a flywheel for the front of the engine. However replacing these units with a multi-piece can help reduce rotational mass as well as removing unwanted or unneeded pulley grooves.

Later units used a multi-piece unit, meaning the damper section is more akin to traditional damper units and uses a bolt-on pulley section. These units can easily be differentiated from other big-block dampers by the large bolt ring for the pulley, and the six pulley bolt holes. Non-industrial dampers (such as those for the 396) have only three pulley bolt holes.

The multi-piece units use specially stamped pulleys that are different than standard big block pulleys and are not interchangable out of the box. Most noticable is the large center bore on the industrial pulleys. These may use various depths or quantity of pulleys depending on the application. This also allowed later engines to use serpentine-style belts or larger diameter pulleys in some applications.

Note that all big block dampers are interchangable in theory; meaning they will attach to the end of the crankshaft. But not all are correct. For instance a 454 damper will attach to a 366 crankshaft and vice-versa, but the 454 is externally balanced and will have counterweight built in. For this reason it is very possible to unwittingly attach the incorrect damper to one of these engines (or purchase one that has the incorrect damper). Because of factory balancing differences with these engines, some machine shops may incorrectly assume the engine requires external balancing (see balancing note at the end of crankshaft section here) and recommend or attach the wrong damper.

Below is a tall deck damper with external weights, such as only a 454 requires. Note this damper is both weighted, and set up for the style used only on factory tall decks. For more info on the tall deck 454 see here.

The multi-piece dampers seem to be readily available online, but we have only so far found one source for one-piece.

Please note the following is not a recommendation, only an availability notice:

--The rare one-piece (1968-1990) damper is available at damperdudes.net here (note this link will take you away from our site): one-piece damper link (damperdudes.net)

Each block and cast part carries a casting number straight from the molds. These are used to identify parts with engineering drawings to determine the as-cast configuration. The casting number does not necessarily tie the part of engine to a specific manufacturing plant.

Parts that emerged from the foundry with the same casting numbers went on to machining, where different operations might be done on them. For instance some blocks with the same casting number could be either 2 or 4 bolt main bearing caps depending on machining (although not in 366/427 engines as all were 4-bolt). A true determination of the engine and its parts cannot rely solely on casting numbers alone, but must also account for any factory stamps added along the line.

Each assembled engine was hand-stamped on the factory line individually on a machined pad above the timing cover that contains: the final plant, production date of engine, and a suffix code designation that may include transmission, carburetor or TBI, special emissions specifications, horsepower rating, and cubic inches.

Since 1956, GM has used the following formats for V8 engine stamps, usually in 3/16" tall characters, stamped at the engine plant before proceeding to the final assembly plant:

First letter: plant designation (see below regarding plant letter codes)

Second through fourth or fifth numbers: date designation (see below regarding assembly date codes)

Any other letters afterward: engine suffix code.

Regarding assembly date codes: For factory installed engines, the engine assembly date is typically a three or four digit number, where the first one or two digits represent the month (1=Jan...12=Dec), and the last two digits represent the day of the month (01 to 31). It is important to note that the engine plants did not use the '1' character. The letter 'I' is used to represent a '1'. This is sometimes confusing, since the assembly date and the suffix code run together.

Regarding Chevrolet engine plant designations:

F=Flint, MI (1955-1966)

V=Flint, MI (1967+)

T=Tonowanda, NY

K=St Catherine, Ontario

S=Saginaw, MI

M=Mexico

Note that the letter 'I' is used in place of the number '1' in pad stamps, except for any VIN derivative stamps.

Example: TII24AHK, which translates to T=Tonowanda, II=November, 24=the 24th(of Nov), AHK=engine suffix code.

Some engines will be stamped with a code starting 'CE' on the pad, usually followed by a series of numbers. This code does not follow the usual format given above. These engines were used to replace bad engines under warranty, or sold over the counter as crate engines.

Regarding service replacement powertrain units, quoting from a Chevrolet Dealer Service Information Bulletin dated 14 April, 1969:

The first letter will designate the GM division which produced the engine. C-Chevrolet L-Oldsmobile K-Cadillac B-Buick P-Pontiac

The second letter will designate the type of unit "E" engine or "T" transmission. The number following the letter will designate the model year "9" for 1969. The last five digits specify the service replacement unit sequence number. The group of numbers to be used by Chevrolet manufacturing plants [for engines, CRG] are as follows:

Flint motor plant (L-6 engines) 00001 to 19999

Flint V-8 engine plant 20000 to 49999

Tonowanda motor plant 50000 to 79999

Example: Number CE900195 designates Chevrolet engine - 1969 year, and the 195th unit produced for service at the Flint motor plant.

This numbering system applies to service engine assemblies, partial engines, fitted cylinder cases, cylinder cases, transmission assemblies and transmission cases.

Factory installed engines may have a VIN derived stamp in 1/8" tall characters, stamped on the final vehicle assembly line. This may be on the pad along with the engine plant stamp, or sometimes by the oil filter boss, or basically wherever they found a location.

In the below picture, The crated engines on the right are tall deck engines easily identifiable by their double thermostat housings:

Following is an (incomplete) list of some of the engine suffix codes used to stamp 366T/427T engines. Note that most of the 'automatic transmission' entries will refer to the four speed Allison AT-540, which according to the SAE was introduced in September 1970 for single-axle drive trucks and buses in the 10,000lb to 36,000lb GVW class.

Code Year CI, HP, Equipment

AAA 1973 366 cubic inch, 200hp, 4 barrel carburetor, Air Injection Reactor (AIR), manual transmission

AAB 1973 427 cubic inch, 230hp, 4 barrel carburetor, Air Injection Reactor (AIR), manual transmission

AAS 1973 427 cubic inch, 230hp, 4 barrel carburetor, manual transmission

ADS 1973 366 cubic inch, 200hp, 4 barrel carburetor, Air Injection Reactor (AIR), manual transmission

ADU 1973 366 cubic inch, 200hp, 4 barrel carburetor, Air Injection Reactor (AIR), automatic transmission

ADV 1973 366 cubic inch, 200hp, 4 barrel carburetor, Air Injection Reactor (AIR), automatic transmission

ADW 1973 366 cubic inch, 200hp, 4 barrel carburetor, Air Injection Reactor (AIR), manual transmission

ADX 1973 366 cubic inch, 200hp, 4 barrel carburetor, Air Injection Reactor (AIR), automatic transmission

ADZ 1973 427 cubic inch, 230hp, 4 barrel carburetor, Air Injection Reactor (AIR), manual transmission

AEA 1973 427 cubic inch, 230hp, 4 barrel carburetor, manual transmission

AFA 1976 366 cubic inch, 200hp, 4 barrel carburetor, manual transmission

AFB 1976 366 cubic inch, 200hp, 4 barrel carburetor, automatic transmission

AFD 1977 366 cubic inch, 200hp, 4 barrel carburetor, Air Injection Reactor (AIR), manual transmission

AFF 1977 366 cubic inch, 200hp, 4 barrel carburetor, automatic transmission

AFH 1977 366 cubic inch, 200hp, 4 barrel carburetor, manual transmission

AFJ 1977 366 cubic inch, 200hp, 4 barrel carburetor, automatic transmission

AFL 1977 366 cubic inch, 200hp, 4 barrel carburetor, manual transmission

AFM 1978 366 cubic inch, 200hp, 4 barrel carburetor, manual transmission

AFR 1978 366 cubic inch, 200hp, 4 barrel carburetor, manual transmission

AFS 1976 366 cubic inch, 200hp, 4 barrel carburetor, automatic transmission

AFT 1973 366 cubic inch, 200hp, 4 barrel carburetor, LP gas, manual transmission

AFT 1974 366 cubic inch, 200hp, 4 barrel carburetor, LP gas, manual transmission

AFU 1973 366 cubic inch, 200hp, 4 barrel carburetor, LP gas, manual transmission

AFU 1974 366 cubic inch, 200hp, 4 barrel carburetor, LP gas, manual transmission

AFU 1978 366 cubic inch, 200hp, 4 barrel carburetor, manual transmission

AHA 1974 366 cubic inch, 200hp, 4 barrel carburetor, manual transmission

AHA 1979 366 cubic inch, 190hp, 4 barrel carburetor, dual exhaust, manual transmission

AHB 1974 366 cubic inch, 200hp, 4 barrel carburetor, automatic transmission

AHB 1979 366 cubic inch, 190hp, 4 barrel carburetor, dual exhaust, automatic transmission

AHC 1979 366 cubic inch, 190hp, 4 barrel carburetor, dual exhaust, manual transmission

AHD 1975 366 cubic inch, 200hp, 4 barrel carburetor, manual transmission

AHD 1976 366 cubic inch, 200hp, 4 barrel carburetor, manual transmission

AHH 1975 366 cubic inch, 200hp, 4 barrel carburetor, manual transmission

AHH 1976 366 cubic inch, 200hp, 4 barrel carburetor, manual transmission

AHH 1979 366 cubic inch, 190hp, 4 barrel carburetor, dual exhaust, manual transmission

AHJ 1975 366 cubic inch, 200hp, 4 barrel carburetor, automatic transmission

AHJ 1976 366 cubic inch, 200hp, 4 barrel carburetor, automatic transmission

AHJ 1978 366 cubic inch, 200hp, 4 barrel carburetor, manual transmission

AHK 1973 366 cubic inch, 200hp, 4 barrel carburetor, manual transmission

AHK 1974 366 cubic inch, 200hp, 4 barrel carburetor, manual transmission

AHL 1975 366 cubic inch, 200hp, 4 barrel carburetor, automatic transmission

AHL 1976 366 cubic inch, 200hp, 4 barrel carburetor, automatic transmission

AHL 1979 366 cubic inch, 190hp, 4 barrel carburetor, dual exhaust, manual transmission

AHM 1973 366 cubic inch, 200hp, 4 barrel carburetor, automatic transmission

AHM 1974 366 cubic inch, 200hp, 4 barrel carburetor, automatic transmission

AHN 1973 366 cubic inch, 200hp, 4 barrel carburetor, manual transmission

AHR 1973 366 cubic inch, 200hp, 4 barrel carburetor, automatic transmission

AHR 1974 366 cubic inch, 200hp, 4 barrel carburetor, automatic transmission

AHR 1978 366 cubic inch, 200hp, 4 barrel carburetor, manual transmission

AHS 1973 366 cubic inch, 200hp, 4 barrel carburetor, manual transmission

AHS 1974 366 cubic inch, 200hp, 4 barrel carburetor, manual transmission

AHS 1978 366 cubic inch, 200hp, 4 barrel carburetor, manual transmission

AHS 1979 366 cubic inch, 190hp, 4 barrel carburetor, manual transmission

AHT 1973 427 cubic inch, 230hp, 4 barrel carburetor, manual transmission

AHT 1978 366 cubic inch, 200hp, 4 barrel carburetor, manual transmission

AHU 1973 427 cubic inch, 230hp, 4 barrel carburetor, manual transmission

AHU 1975 366 cubic inch, 200hp, 4 barrel carburetor, manual transmission

AHU 1976 366 cubic inch, 200hp, 4 barrel carburetor, manual transmission

AHU 1977 366 cubic inch, 200hp, 4 barrel carburetor, manual transmission

AHW 1973 427 cubic inch, 230hp, 4 barrel carburetor, manual transmission

AHW 1975 366 cubic inch, 200hp, 4 barrel carburetor, automatic transmission

AHW 1976 366 cubic inch, 200hp, 4 barrel carburetor, automatic transmission

AHW 1977 366 cubic inch, 200hp, 4 barrel carburetor, automatic transmission

AHX 1975 366 cubic inch, 200hp, 4 barrel carburetor, manual transmission

AHX 1976 366 cubic inch, 200hp, 4 barrel carburetor, manual transmission

AHX 1977 366 cubic inch, 200hp, 4 barrel carburetor, manual transmission

AHY 1975 366 cubic inch, 200hp, 4 barrel carburetor, manual transmission

AHY 1976 366 cubic inch, 200hp, 4 barrel carburetor, manual transmission

AHY 1977 366 cubic inch, 200hp, 4 barrel carburetor, manual transmission

AHZ 1975 366 cubic inch, 200hp, 4 barrel carburetor, automatic transmission

AHZ 1976 366 cubic inch, 200hp, 4 barrel carburetor, automatic transmission

AHZ 1977 366 cubic inch, 200hp, 4 barrel carburetor, automatic transmission

AJA 1977 427 cubic inch, 220hp, 4 barrel carburetor, automatic transmission

AJB 1973 366 cubic inch, 200hp, 4 barrel carburetor, automatic transmission

AKA 1975 427 cubic inch, 220hp, 4 barrel carburetor, manual transmission

AKA 1976 427 cubic inch, 220hp, 4 barrel carburetor, manual transmission

AKA 1977 427 cubic inch, 220hp, 4 barrel carburetor, manual transmission

AKA 1979 427 cubic inch, 220hp, 4 barrel carburetor, manual transmission

AKB 1975 427 cubic inch, 220hp, 4 barrel carburetor, manual transmission

AKB 1976 427 cubic inch, 220hp, 4 barrel carburetor, manual transmission

AKB 1977 427 cubic inch, 220hp, 4 barrel carburetor, manual transmission

AKB 1979 427 cubic inch, 220hp, 4 barrel carburetor, manual transmission

AKC 1975 427 cubic inch, 220hp, 4 barrel carburetor, manual transmission

AKC 1976 427 cubic inch, 220hp, 4 barrel carburetor, manual transmission

AKC 1977 427 cubic inch, 220hp, 4 barrel carburetor, manual transmission

AKC 1979 427 cubic inch, 220hp, 4 barrel carburetor, manual transmission

AKD 1975 427 cubic inch, 220hp, 4 barrel carburetor, Air Injection Reactor (AIR), manual transmission

AKD 1976 427 cubic inch, 220hp, 4 barrel carburetor, Air Injection Reactor (AIR), manual transmission

AKD 1977 427 cubic inch, 220hp, 4 barrel carburetor, Air Injection Reactor (AIR), manual transmission

AKD 1979 427 cubic inch, 220hp, 4 barrel carburetor, manual transmission

AKF 1978 427 cubic inch, 220hp, 4 barrel carburetor, manual transmission

AKH 1975 427 cubic inch, 220hp, 4 barrel carburetor, Air Injection Reactor (AIR), manual transmission

AKH 1976 427 cubic inch, 220hp, 4 barrel carburetor, Air Injection Reactor (AIR), manual transmission

AKH 1977 427 cubic inch, 220hp, 4 barrel carburetor, Air Injection Reactor (AIR), manual transmission

AKH 1979 427 cubic inch, 220hp, 4 barrel carburetor, manual transmission

AKJ 1975 427 cubic inch, 220hp, 4 barrel carburetor, Air Injection Reactor (AIR), manual transmission

AKJ 1976 427 cubic inch, 220hp, 4 barrel carburetor, Air Injection Reactor (AIR), manual transmission

AKJ 1977 427 cubic inch, 220hp, 4 barrel carburetor, Air Injection Reactor (AIR), manual transmission

AKJ 1979 427 cubic inch, 220hp, 4 barrel carburetor, manual transmission

AKK 1976 366 cubic inch, 200hp, 4 barrel carburetor, manual transmission

AKK 1978 427 cubic inch, 220hp, 4 barrel carburetor, manual transmission

AKL 1976 366 cubic inch, 200hp, 4 barrel carburetor, automatic transmission

AKL 1977 366 cubic inch, 200hp, 4 barrel carburetor, automatic transmission

AKM 1976 366 cubic inch, 200hp, 4 barrel carburetor, manual transmission

AKM 1977 366 cubic inch, 200hp, 4 barrel carburetor, manual transmission

AKM 1979 427 cubic inch, 220hp, 4 barrel carburetor, automatic transmission

AKR 1976 366 cubic inch, 200hp, 4 barrel carburetor, automatic transmission

AKR 1977 366 cubic inch, 200hp, 4 barrel carburetor, automatic transmission

AKS 1976 427 cubic inch, 220hp, 4 barrel carburetor, manual transmission

AKS 1977 427 cubic inch, 220hp, 4 barrel carburetor, manual transmission

AKT 1974 427 cubic inch, 230hp, 4 barrel carburetor, manual transmission

AKT 1978 427 cubic inch, 220hp, 4 barrel carburetor, manual transmission

AKU 1974 427 cubic inch, 230hp, 4 barrel carburetor, manual transmission

AKU 1978 427 cubic inch, 220hp, 4 barrel carburetor, manual transmission

AKW 1974 427 cubic inch, 230hp, 4 barrel carburetor, manual transmission

AKX 1976 427 cubic inch, 220hp, 4 barrel carburetor, Air Injection Reactor (AIR), manual transmission

AKX 1977 427 cubic inch, 220hp, 4 barrel carburetor, Air Injection Reactor (AIR), manual transmission

ALA 1977 427 cubic inch, 220hp, 4 barrel carburetor, automatic transmission

ALB 1977 427 cubic inch, 220hp, 4 barrel carburetor, automatic transmission

ALC 1977 427 cubic inch, 220hp, 4 barrel carburetor, Air Injection Reactor (AIR), automatic transmission

ALD 1977 427 cubic inch, 220hp, 4 barrel carburetor, Air Injection Reactor (AIR), automatic transmission

ALF 1977 427 cubic inch, 220hp, 4 barrel carburetor, manual transmission

ALK 1978 427 cubic inch, 220hp, 4 barrel carburetor, manual transmission

ALM 1978 427 cubic inch, 220hp, 4 barrel carburetor, manual transmission

ALS 1978 427 cubic inch, 220hp, 4 barrel carburetor, manual transmission

ARM 1978 366 cubic inch, 200hp, 4 barrel carburetor, manual transmission

ATA 1975 366 cubic inch, 200hp, 4 barrel carburetor, automatic transmission

ATB 1975 366 cubic inch, 200hp, 4 barrel carburetor, manual transmission

ATB 1976 366 cubic inch, 200hp, 4 barrel carburetor, manual transmission

ATB 1977 366 cubic inch, 200hp, 4 barrel carburetor, manual transmission

ATC 1975 366 cubic inch, 200hp, 4 barrel carburetor, automatic transmission

ATC 1976 366 cubic inch, 200hp, 4 barrel carburetor, automatic transmission

ATC 1977 366 cubic inch, 200hp, 4 barrel carburetor, automatic transmission

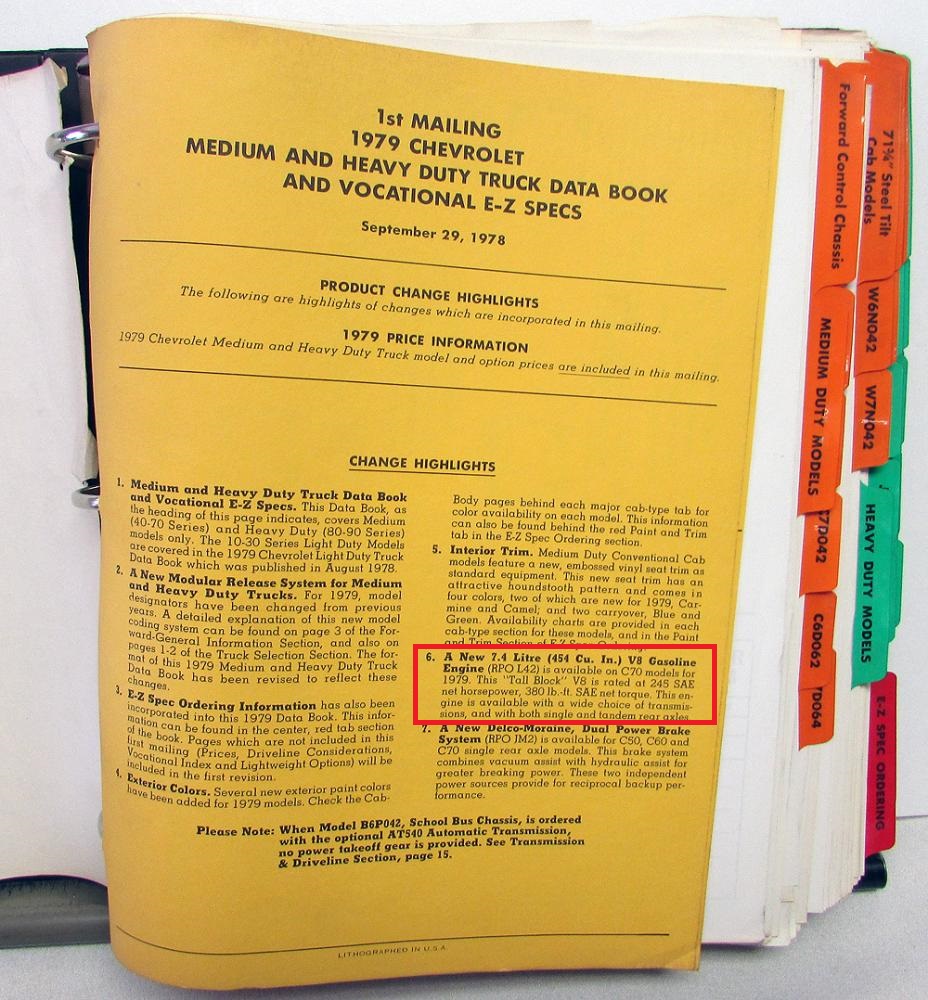

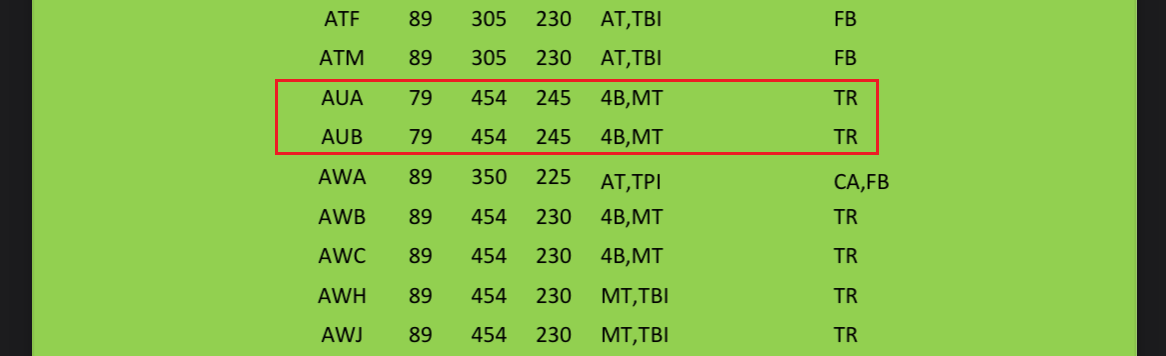

AUA 1979 454 cubic inch, 245hp, 4 barrel carburetor, manual transmission

AUB 1979 454 cubic inch, 245hp, 4 barrel carburetor, manual transmission (possible error in Lime Book, may be automatic)

AUC 1980 454 cubic inch, 245hp, 4 barrel carburetor, manual transmission

TCM 1970 366 cubic inch, 235hp, 4 barrel carburetor, manual transmission

TMC 1970 366 cubic inch, 235hp, 4 barrel carburetor, manual transmission

TMD 1970 366 cubic inch, 235hp, 4 barrel carburetor, manual transmission

TMF 1970 366 cubic inch, 235hp, 4 barrel carburetor, manual transmission

TMG 1970 366 cubic inch, 235hp, 4 barrel carburetor, manual transmission

TMH 1970 366 cubic inch, 235hp, 4 barrel carburetor, manual transmission

TMI 1970 427 cubic inch, 260hp, 4 barrel carburetor, manual transmission

TTW 1970 366 cubic inch, 235hp, 4 barrel carburetor, manual transmission

TTX 1970 366 cubic inch, 235hp, 4 barrel carburetor, manual transmission

TTZ 1970 427 cubic inch, 260hp, 4 barrel carburetor, manual transmission

TYX 1970 366 cubic inch, 235hp, 4 barrel carburetor, manual transmission

WZ 1966 366 cubic inch, 222hp, automatic transmission

XXY *this code appears on some block castings 473478 but not recorded in documentation

YA 1966 366 cubic inch, 222hp, manual transmission

YA 1969 366 cubic inch, 235hp, 4 barrel carburetor, automatic transmission

YB 1966 366 cubic inch, 222hp, manual transmission

YB 1969 366 cubic inch, 235hp, 4 barrel carburetor, manual transmission

YC 1969 366 cubic inch, 235hp, 4 barrel carburetor, manual transmission

YD 1969 366 cubic inch, 235hp, 4 barrel carburetor, automatic transmission

YG 1966 366 cubic inch, 222hp, automatic transmission

YH 1969 366 cubic inch, 235hp, 4 barrel carburetor, automatic transmission

YI 1969 366 cubic inch, 235hp, 4 barrel carburetor, manual transmission

YJ 1969 366 cubic inch, 235hp, 4 barrel carburetor, automatic transmission

YK 1969 366 cubic inch, 235hp, 4 barrel carburetor, manual transmission

YT 1966 366 cubic inch, 222hp, manual transmission

YT 1967 427 cubic inch, 260hp, manual transmission

YT 1969 427 cubic inch, 260hp, 4 barrel carburetor, manual transmission

YU 1967 427 cubic inch, 260hp, manual transmission

YU 1969 427 cubic inch, 260hp, 4 barrel carburetor, manual transmission

YV 1969 427 cubic inch, 260hp, 4 barrel carburetor, manual transmission

YW 1967 427 cubic inch, 260hp, manual transmission

YX 1966 366 cubic inch, 222hp, automatic transmission

YZ 1966 366 cubic inch, 222hp, manual transmission

From the start of GM, a lot of truck and industrial engines of all displacements and types were painted gray, unlike their car counterparts, although as always there were exceptions. GM comprised many brands and each had their own preferences. Unfortunately many photos of GM production plants before the 1970's were black and white. Obviously not all, but GM seemed less concerned about documenting industrial engine production than those intended for regular consumer cars. For these reasons it is difficult to arrive at exactly what color engines were when they left the production lines. From the 1970's onward there were certain corporate mandates that appeared regarding engine colors but before this point is vague at best on specific color guidelines. If you have any color photos of tall deck engine production in any capacity please let us know!

Production colors for GM tall deck engines:

--1966 until approximately 1967-1968: industrial gray

--From approximately 1967-1968 until late 1976/early 1977: Chevrolet orange

--From late 1976/early 1977 until late 1981/early 1982: GM corporate blue

--After late 1981/early 1982: black/gray

It appears that no 4 barrel units, or 427 cubic inch units before the 1980's were painted gray from the factory. (If you have any data or photos to contradict this please contact us!)

This 2 barrel carburetor 1966 unit is painted gray:

Originally GM divisions had their own colors for their own engines, even with different displacment or options having different colors. Some divisions used gold or blue like Pontiac or Oldsmobile, or black, or gray, or various shades or teal or aqua. But all Chevrolet big block V8's before late 1976/early 1977 were Chevrolet orange or industrial gray.

There does not seem to be an exact color changeover date, and it would make sense that no date could be solidified as engines dropped into vehicles were not installed in the precise order they came out of engine production plants.

The color change to corporate blue in late 1976/early 1977 was driven by GM's desire to interchangably use different division engines in vehicles, such as using the more available Chevrolet 350 in place of the less available Oldsmobile 350 where needed to speed production. This precise situation led to a lawsuit in which GM was accused of engine substitution without customer or dealer knowledge. In reality this was true as GM had an Oldsmobile engine shortage and was hoping no one would notice if all GM corporate division drivetrains were colored the same.

Chevrolet orange paint codes:

--Duplicolor: DE 1607

--PPG/Ditzler: 6033

GM Corporate Blue paint codes:

--Ames: Corporate Blue FN411

--Classic Industries: GM Corporate Blue 62030

--Duplicolor: General Motors Blue DE 1608

--PPG/Ditzler: Blue 15159

--VHT Paints: GM Blue SP-135

Targetmaster replacement engines:

Sources indicate all Targetmaster engines were painted the same colors as the regular production engines for the years they were made.

Goodwrench replacement engines:

All GM Goodwrench big block engines are black/gray, being produced after GM's switch to this color for all engines.

A 1978 tall deck painted in blue:

It seems that all engines up until 1968 were 2bbl versions. Documentation indicates that the 4bbl was not offered until 1968. Our sources vary for when 2bbl production actually ended. Some sources say 2bbl carburetors were not offered after 1968, however other sources indicate it was an available (if not often ordered) option until 1972. For certain, 2bbl options were not offered after 1972.

Documentation from carburetor manufactors (sales data) shows no 2bbl carburetors on big block truck engines after 1967. 1966 and 1967 show no 4bbl option on big block truck engines.

1966-1967 used a 2bbl Rochester 2G (vacuum governor) carb no. 7026113, using rebuild kit 7016629.

1968-1973 used a 4bbl Holly 4150G (vacuum governor).

1974-1979 used a 4bbl Holly, version unknown at this time.

1980-1990 used a 4bbl Holly 4152EG (electric over vacuum governor).

The 4150MG (mechanical governor) does not appear to have been used.

Early carbureted engines have standard big block stamped-steel valve covers. The TBI (Throttle Body Injection) versions of the tall deck engines have a different intake manifold, with two intake ports on top rather than the four for the Holley 4150G governed carburetor. There will also not be a mechanical fuel pump mounted on the block, and some later blocks may not have a provision for one. The rocker arm covers also switched to a more modern-looking, cast, finned design for these later engines. Later engines will have stickers specifiying cubic inch displacement on each valve cover, in red or white letters.

The early two barrel carbureted versions are almost all painted orange or gray. Four barrel carbureted versions are almost all painted orange or blue from the factory, while the later TBI and carbureted units are all factory black or gray, especially after the generation changeover in 1990-1991.

Early tall deck engines (carbureted):

Later tall deck inch engines (TBI):

Fuel injection was first fitted to big blocks starting in 1988, although not necessarily to the industrial 366 and 427 which seem to have waited until the block generation changeover in 1990-1991, with fuel injection starting in the model year 1989. Note that because of being a changeover year, there may be some overlap. The ECM and coding seem to be mostly the same as the OBD I specification used on the small block engines with physically only the injector and throttle body size being increased to match the big block (if you have any information on the ECM coding vs regular engines please let me know). Carbureted and FI engines were produced concurrently for specific uses on marine and bus applications after the TBI system was introduced, so factory carbureted applications can be found well past the TBI introduction dates. Since these are industrial engines, there is a wide overlap of dates when different systems were used.

Note that although GM switched to the OBD II standard in 1996 for regular cars, this did not translate to large trucks that used these engines.

Some later block castings still have bosses for mechanical fuel pumps, to support the use of carburetion after the TBI system was introducted in the 1990's.

One primary thing to note is that most Edelbrock or Carter will not work out-of-the-box (OOTB). Adjustments will most likely be required, including jets and metering rods. Most of these are tuned for small blocks or common engines OOTB, and the tall deck is not a common engine but has specific requirements.

Some Edelbrock/Carter carburetors will bolt up directly to the square bore manifold, but any carburetor with even slightly larger secondaries should be double-checked to ensure all throttle butterflies open completely inside the bores. If not, a spacer or adapter may have to be used.

Removing the factory Holley carburetor will remove governor functionality, so consider this in your swap.

Some Edelbrock/Carter carburetors may be more finicky on fuel supply volume and pressure than the original Holley. These carburetors do not have a tremendously large fuel bowl, so they require an even and constant fuel supply at good pressure. Any fuel irregularities, especially under heavy throttle, may cause poor running characteristics.

Also note that most Edelbrock/Carter carburetors do not have all mechanical adjustments complete OOTB. The secondaries may not open fully until the tangs and rods are adjusted, and the accelerator pump rod may not be in the correct hole, among other things. The carburetor should be carefully gone over before and during installation to ensure everything is adjusted within specification.

The Carter AFB is very similar to the Edelbrock in almost every way. Jets and rods are almost all interchangable, along with almost all other parts. Edelbrocks are newer, while the Carter AFB was the original iteration of this design.

Choose the carburetor carefully, as things like CFM and throttle butterfly size will affect the performance. While metering rod and jet tuning can be performed to account for this a little, the initial CFM selection is very important. From our experience, these engines do like a lot of air and fuel under heavy throttle, so the secondary adjustments may need to account for that. Every carburetor will perform a little differently, especially as height above sea level varies, etc. Take all conditions into consideration when tuning.

Following is an example for a specific tune, tuned with an AFR (air/fuel ratio) guage under all throttle conditions, for use in south-eastern Pennsylvania. As can be seen from the specifications, the jet and rod requirements differ very far from out-of-the-box specs.

Engine: 366 tall deck, all factory specifications, HEI conversion.

Carburetor: New out of the box Carter AFB competition 9000 series carburetor, 9755S 2565.

Note: Carburetor requires adapter plate for secondaries to open fully on standard tall deck intake manifold.

Accelerator pump rod: middle hole.

Primary metering rods: 0.070 x 0.037 primary rods with orange spring.

Jets: 0.116 jets main, 0.113 secondary jets.

Electric choke: Edelbrock 1478 electric choke conversion kit.

Following is a tuning history for this engine/carburetor as these specifications and progressions may help others as they tune to see the variations in performance associated with various changes.

--Initial tune: 120-404 .104 primary jets, .104 secondary jets. Carb hesitates with accelerator pump rod on uppermost hole, less hesitation on middle hole, even less hesitation on lowest hole but still hesitates. AFR far out of spec., not very driveable.

--Tune 1: 16-691 .076 x .055 + orange spring, accel pump in lowest hole. accel hesitation, low power, backfires through exhaust during mid throttle and wide open throttle.

--Tune 2: 16-485 .065 x .052 + silver spring, accel pump in lowest hole. no hesitation, no backfires, better low to mid throttle power, low on wide open throttle power.

--Tune 3: 16-241 .0705 x .0475 + pink spring, accel pump in middle hole. No hesitation, no backfires, runs hot, exhaust manifolds too hot, AFR too lean.

--Tune 4: .113 main jets, .107 secondary jets. Rods .068x .047 #1447. Orange spring. Accelerator pump in middle hole. Runs ok but backfires and low power under heavy throttle.

--Tune 5: .116 jets main, .113 secondary jets. Rods .0705 x .0475 16-241, organge spring, accelerator pump in middle hole. Runs good, slightly rich AFR except when secondaries open and stay open at heavier throttle. Could use some more fuel on accelerator pump according to AFR.

--Tune 6: accelerator pump in top hole, silver metering springs. Still goes lean, but stumbles under accelerator stab.

--Tune 7: accelerator pump in middle hole, silver springs. Ok throttle response, still lean spike under heavy throttle or load, i.e. Going up hills, etc. stumbles.

--Tune 8: .070x.037 primary metering rods, orange spring, adjusted idle for AFR, screws about .75 turns out approximately. Good all around performance, leans out under load sometimes.

--Tune 9: readjusted idle for richer running, runs better when rich. Added second booster fuel pump, no more lean conditions under heavy throttle.

For a quick look at Edelbrock and Carter manuals, see here or here. For a quick look at older Carter series comparisons, see chart below.

All Edelbrock and Carter carburetors have a standard 5-1/8" airhorn for mounting air cleaner.

Carter AFB measurements by series/model (incomplete list):

Carb# | CFM | Venturi Diameter(in.) | Bore Diameter(in.)

4121 | | 1-1/16 | 1-1/4 | 1-7/16 | 1-9/16

4122 | | 1-1/16 | 1-1/4 | 1-7/16 | 1-9/16

4132 | | 1-1/16 | 1-9/16 | 1-7/16 | 1-9/16

4133 | | 1-1/16 | 1-9/16 | 1-7/16 | 1-9/16

4136 | | 1-1/16 | 1-9/16 | 1-7/16 | 1-9/16

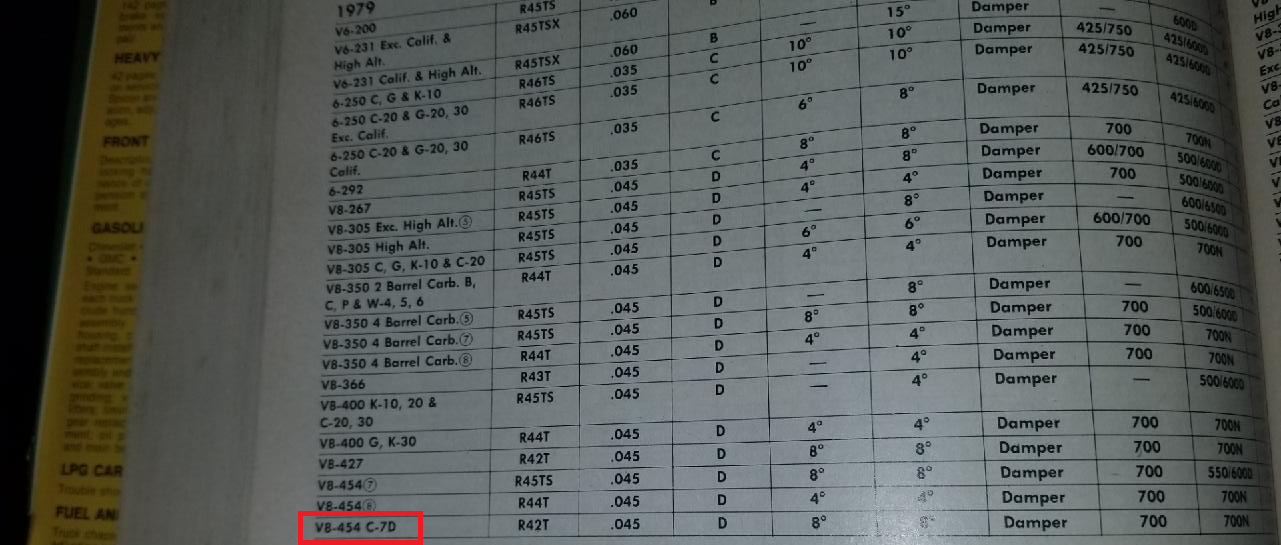

4137 | | 1-1/16 | 1-9/16 | 1-7/16 | 1-9/16